Long service life thanks to polymer plain bearings in bag forming, filling and sealing machine

Despite adverse conditions, maintenance-free packaging machine thanks to drylin linear bearings

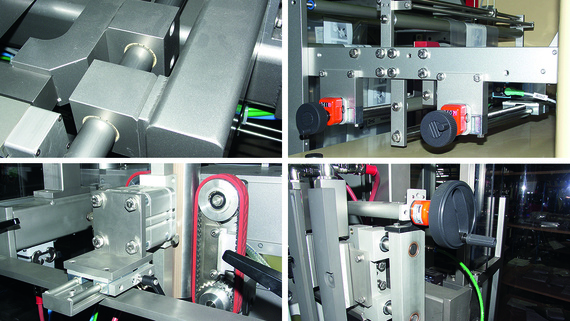

Linear plain bearings and films are used in the bag forming, filling and sealing machines of Hastamat Verpackungstechnik GmbH. They guarantee long service life on the transverse sealing tools and in the area of the longitudinal sealing unit despite unfavourable ambient conditions, which are mainly characterised by dust, powder deposits and moisture.Profile

- What was needed: igubal spherical bearings, drylin R shaft guides, drylin R linear plain bearings, drylin SET easytube linear axis, drylin W clamping units

- Requirements: The machine parts are exposed to dust, powder deposits, and moisture during the packaging process. They must be quick to change over and quick and easy to clean. The entire system is in continuous operation.

- Industry: Packaging technology

- Success for the customer: The plastic bearings withstand all external influences and ensure the necessary service life. Lubrication-free bearings prevent product contamination. This means that the bearing technology requires absolutely no maintenance.

Products used

Problem

Linear and rotary bearings are required on the multi-head weighers, the transverse sealing tools and the longitudinal sealing unit of this bag forming, filling and sealing machine, which have to meet different requirements.Warm, cold, dusty or damp: These are just some of the challenges that bag forming, filling and sealing machines made by Hastamat Verpackungstechnik GmbH in Lahnau near Gießen, Germany, face when packaging a wide variety of products. For this purpose, they must be simple to operate and clean. The demands on the mounted machine elements are correspondingly high.

During the packaging process, dust, powder deposits and moisture are the rule. The machine is often only roughly cleaned after production or simply blown off with compressed air. There are only two constructive options here. Either the entire system should be elaborately sealed up, or use machine elements that can deal with this dirt accumulation without breaking down early.

Working in continuous operation without operating personnel, quick to retrofit, easy to clean are further essential components of the machine concept.

Solution

Plastic plain bearings on the machine stations defy all external influences and ensure the necessary service life. Matched to each other, they are easy to install and, because they are absolutely maintenance-free, product contamination by lubricants never occurs. This also means that there is no build-up of bacteria and dirt, which must be removed at great expense.

Multi-head weighers

The igubal double spherical bearings are used for the container actuation of the flap opening mechanism on the multi-head weighers. They are just as insensitive to dust and dirt as they are maintenance-free and durable.

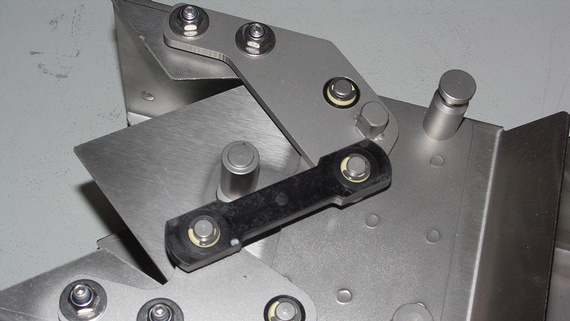

Transverse sealing tool

At the bearing of the transverse sealing tools on the sealing bar, maintenance-free liners are used in combination with hard anodised aluminium shafts. They are composed of a wear-resistant iglidur material. The tribologically optimised high-performance polymer is predestined for applications in which the plain bearing elements should attain maximum running performances. The dimensions are compatible with standard ball bushings. The special geometry guarantees reliability even in extreme environments. Even wash-down applications pose no problems.

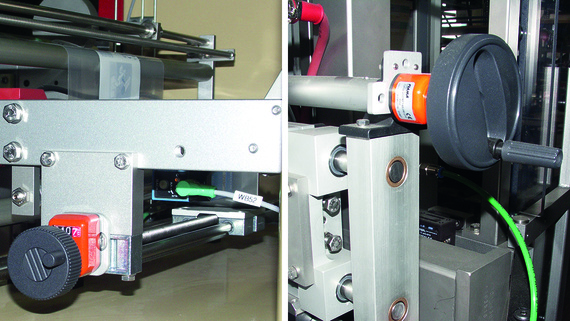

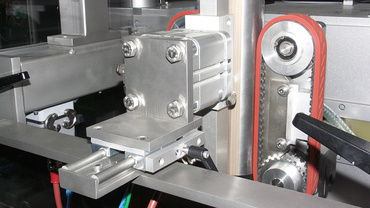

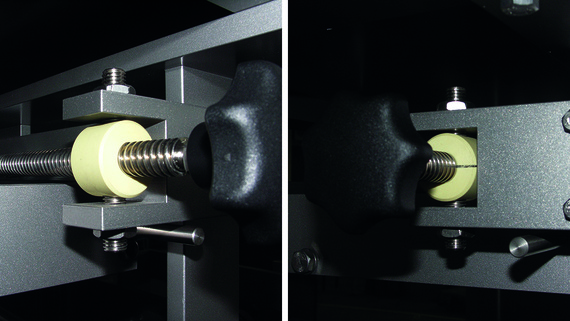

Transverse sealing unit

In the area of the longitudinal sealing unit, four drylin easytube linear units are used for adjustment tasks. The user has two options. You can manually adjust the adjustment carriage using drylin W clamping units in the format adjustment, or do it automatically through the drylin easytube positioning device. When changing formats, the user always finds his exact position, thus avoiding setting errors.