Compact rotating energy supply system for a heavy duty crane on a pipe-laying vessel

Rotary module for cable guidance on heavy-duty cranes, ready to connect

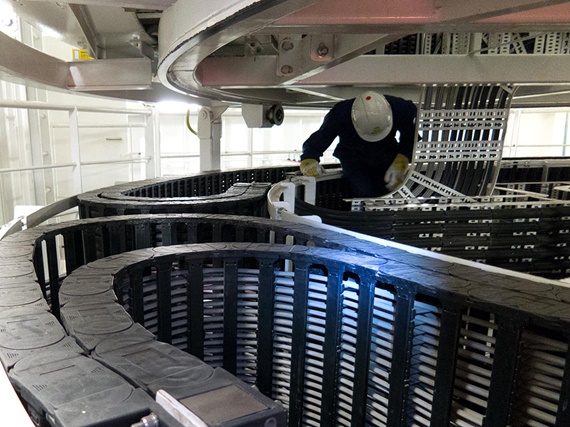

A rotary module with internal energy chains is used to ensure cable guidance in a heavy duty crane on a pipe-laying vessel. Interlocking e-chains allow an especially space-saving design. The solution ensures safe guidance of data and signal cables and hydraulics to maximize rig service life and reduce maintenance requirements.

It was tailored to fit the installation space in the crane platform and delivered ready-to-connect for quick and easy on-site installation.

Profile

- What was needed: Rotating energy supply

- Requirements: Flawless cable guidance at large angles of rotation and under environmental conditions at sea

- Industry: Offshore

- Success for the customer: A rotary energy supply system individually tailored to the crane platform ensures flexible crane movement. All components were individually designed and delivered ready for connection.

Problem

Offshore knuckle boom cranes for the oil and gas industry primarily ensure safe, efficient handling of pipes and other work equipment in such applications as drilling vessels.

Installed in central locations on the vessels, they are intended to cover as wide an area as possible. That means that wide, flawless handling crane rotation is essential. Rotating energy supply systems are used for safe cable guidance.

In this application – a heavy duty crane on a pipe-laying vessel – the requirements for this energy supply system are very high. The large number of data and signal cables and the hydraulics resulted in a great weight that had to be moved safely by the guidance system. There was also a problem of space in the compact crane platform.

Solution

For the flexibly rotating offshore knuckle boom crane, only a rotating energy supply system was considered. It consists of circular trough guides with a matching energy chain design. The systems are designed to guide the largest possible number of cables in the smallest possible installation space. To save additional space, an open-design trough system with interconnected energy chains was selected. Today, it ensures very long service life and minimal maintenance effort.

We designed the rotary module, including the e-chains, for the installation space and delivered them ready for connection. This enabled quick, uncomplicated on-site installation. Our team of supervisors also took responsibility for acceptance and supervision.