Operating safety and service lives clearly increased

Robotic applications: Secure energy supply system for multi-dimensional motion

In production, assembly and handling technology, nothing works anymore in many areas without robots. They execute very complex, multi-dimensional motions within the shortest time. The robot places the filled ampoules and/or drug bottles pallet-wise in a lattice box. The number of freely hanging electrical and pneumatic cables should be bundled together. The specific movements executed by the robot strain the energy cables to a high degree. The jumbled pile of countless electrical and pneumatic cables could finally be bundled in triflex® R. The entire plant today looks compact and clean at first sight.Multi-dimensional motions

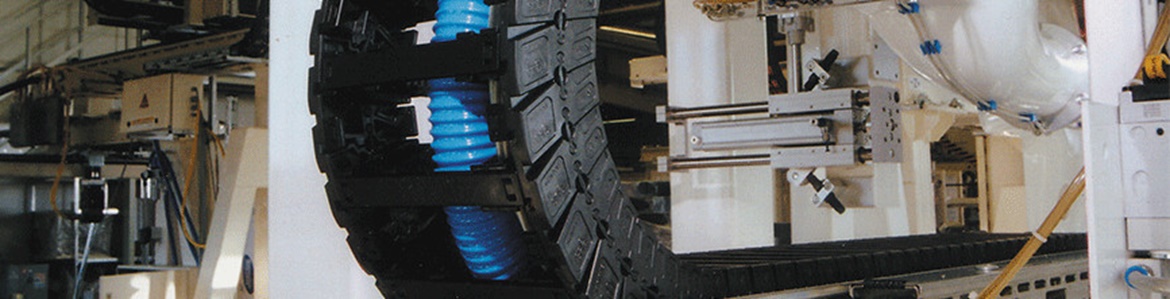

The triflex® series from the house of igus® GmbH, Cologne, was developed to implement a secure energy supply for multi-dimensional motions in the room. Here, the mobility of a hose is combined with the stability of an energy chain and its defined bending radii. At Bayer, special value is placed, among others, to exclude the use of particle accelerator in the area of the filling, as work is conducted under clean room conditions and in air conditioned environment.triflex® R is a new system with several technical highlights. An enclosed exterior contour provides protection against dirt and dust. Due to its round design, it glides over the exterior contour of the robot. For this reason it doesn't get caught or twisted.

The triflex® system is most impressive when dealing in movements in more than two directions. They are primarily used in 6-axis robots found for instance in all environments with welding and painting applications, and in the adhesive and grinding technologies. It is also used in the selective compliance assembly robot arm (SCARA) at extremely high speeds. Fiber rods can be integrated in triflex® R in order to assimilate selective cambers. They grant the energy supply system a certain arrangement and for instance keep them away from interfering edges.