ADVOCUT

Darmstadt Technical University

Project team:

Matthias Weigold, Michael Kulok (Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen TU Darmstadt)Task:

Design of a machine tool with highly integrated mechatronic milling modulePrecision and excellent quality save time and money

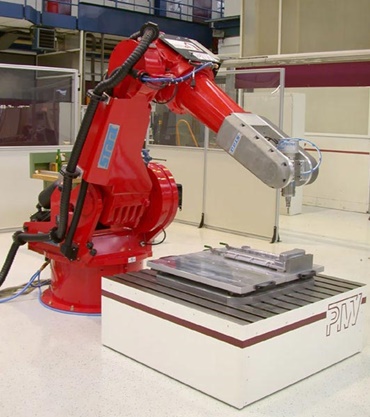

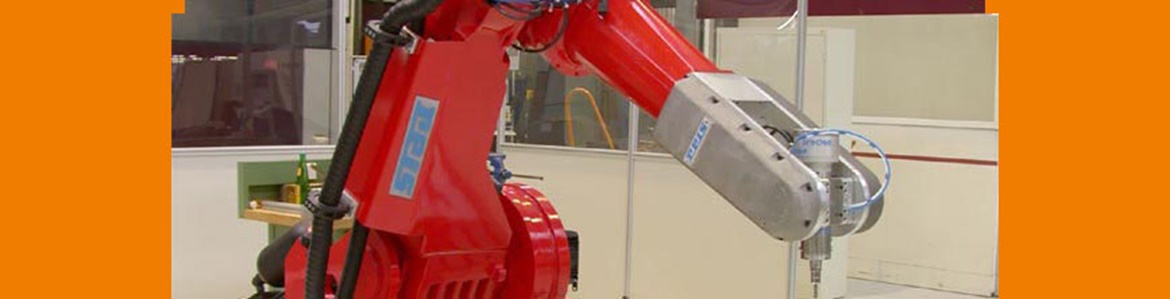

Surface works on large, difficult to access workpieces are often executed by tedious manual work. The project ADVOCUT (aided by the German Federal Ministry for Education and Research) wants to change that. In future, easy milling tasks should operate fully automatically. ADVOCUT is designed for the serial application, for instance in the spare parts production. Thus companies can organize processes that are intensive with regard to costs, personnel and time in an essentially economical way and save time and money on a long term.

Emphasis of the research and development works of the student team is the maximization of accuracy. "No easy enterprise," declares Michael Kulok, staff of the Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen at the TU Darmstadt. He is however convinced that an efficiently operating machine will be developed before the end of the project in September 2006.

The greatest challenge for the research team from Darmstadt is to combine the advantages of the robot-like, fully serial design principle with the merits of the conventional machine tools. Flexibility, movement quality and precision are to be combined in the novel machine tool concept.

igus® came into the picture when the cable running outside the robot had be protected and maximum flexibility ensured at the same time. With Triflex® R C70, the students were right on the mark. The exceedingly moveable energy chain offers not only protection against dirt accumulation. It is moreover predestined for multiaxial rotations. Notwithstanding high speeds and intensive application, the wear is extremely low, which brings the students closer to their subordinate goal of cost-saving by a long way despite multifunctional application.