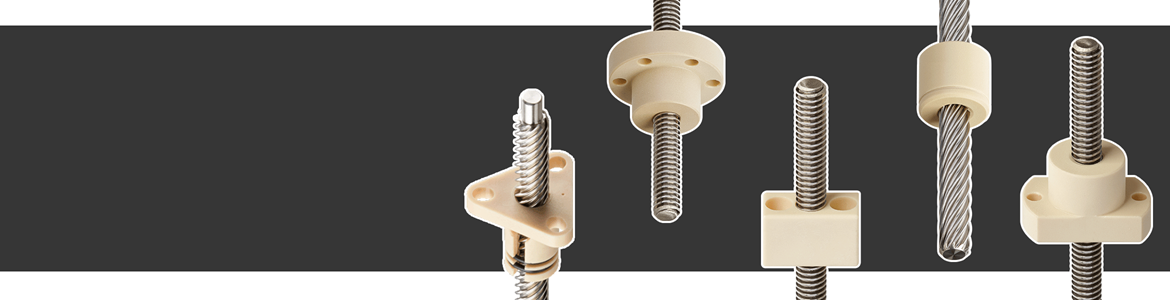

dryspin® lead screw applications

dryspin® lead screw technology is self-lubricating, as stainless-steel or hard anodized aluminum screws are combined with tribologically-optimized iglide® plastic bearings. By eliminating lubrication, the highest hygiene requirements can be met. These features, as well as quiet operation and corrosion-resistance, ensure high performance and extended service life in applications including format adjustments, medical technology, bottling plants or 3D printing.

Typical industrial sectors and applications: Classic format adjustments and lifting applications can be implemented with the self-locking trapezoidal thread.

Typical industrial sectors and applications: Classic format adjustments and lifting applications can be implemented with the self-locking trapezoidal thread.

Lead screw nut in an edge-gluing machine

Lubricant and clearance-free lead screw nut system ensures precision glue dispensing on an edge-gluing machineLead screw nut in an edge-gluing machine