Configure, design and test products with augmented reality

Quicker design process

Augmented reality for maximum transparency and system security

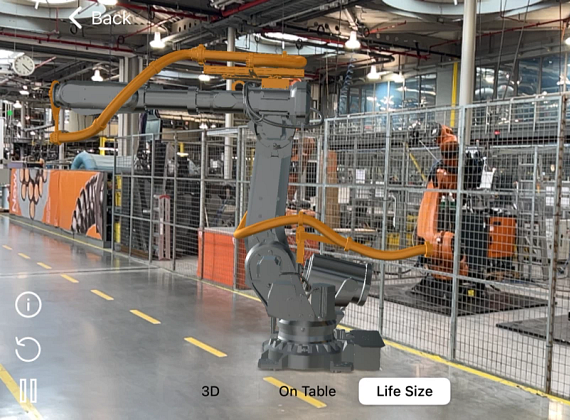

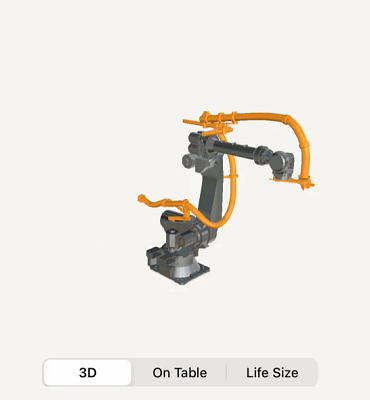

Imagine: You are examining your design not just on a screen, but the virtual model in the reality. You can really do it with the AR feature that igus will integrate into the online tool platform. This is how it works: You configure the product, design and test the AR model. The result is more transparency and planning security and a faster design process. You can use your smartphone, tablet, or data glasses to view virtual models in the reality. And you can design different models for maximum ease of viewing. Benefit from fast, cost-effective feasibility studies and check product integration in advance. In this way, you save time and costs and recognise possible errors even before a prototype is created - on the virtually projected model of the digital twin.

Ron, a senior engineer at a mechanical engineering company, is currently planning a larger facility. In order to ensure that the robot fits into the production environment and that suboptimal design details are detected and corrected at an early stage, he is testing the igus augmented reality software for the first time. He looks at the true-to-scale 3D system models in the iguverse on his tablet and projects them into the real environment as a virtual model. In some cases, feasibility studies help him find the best detailed solution. Ron is enthusiastic and sees igus inside as a glimpse into the future of system planning, where he can save time and money.

How to plan your application with igus augmented reality

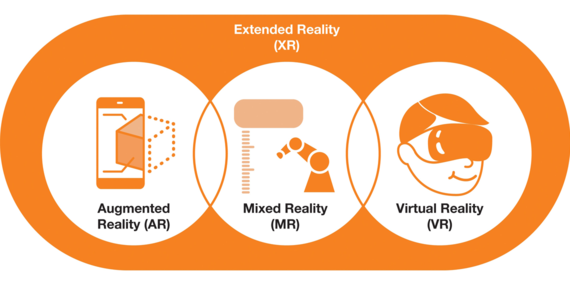

Blog: “How could the manufacturing industry utilize extended reality?”

Virtual reality, augmented reality and mixed reality are impacting manufacturing in a major way. More and more companies are adopting these technologies, and seeing massive benefits. Read the blog to find out how you can do the same.

Your benefits from augmented reality

Tech up

- Check construction design as a virtual model in reality

- Maximum transparency and planning reliability

- Quicker design process

- Check product integration in advance

- Cost-effective, time-saving gateway to the world of Industry 4.0

Cost down

- Fast and more cost-effective feasibility studies instead of complicate, time-consuming CAD visualisation

- Identify potential errors at an early stage to save rework costs during development

Sustainability

- Fewer physical prototypes needed, so less waste and emissions