iguverse: the industrial metaverse of igus

We bring sales and engineering into virtual reality

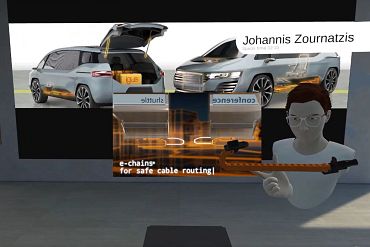

Immerse yourself in the virtual sales and engineering world of the iguverse. Discover new and fascinating ways to save time, money and resources in product development, optimisation and maintenance. The iguverse will simplify your engineering! Use the iguverse as an efficient and user-friendly platform for sustainable product development and fast prototype production. Benefit from two main advantages:- Advantage 1: distance no longer matters. Members from all over the world can meet as avatars in digital space and exchange ideas.

- Advantage 2: projects become clearer and more tangible from Day 1.

Discover the iguverse and become a beta tester

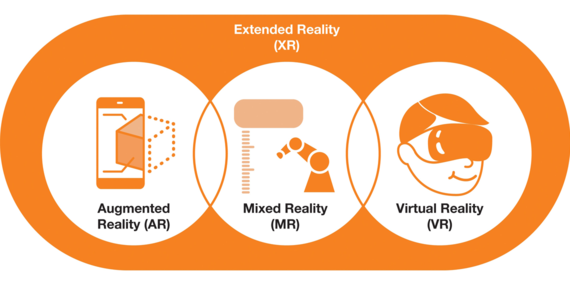

Blog: “How could the manufacturing industry utilize extended reality?”

Virtual reality, augmented reality and mixed reality are impacting manufacturing in a major way. More and more companies are adopting these technologies, and seeing massive benefits. Read the blog to find out how you can do the same.

Read the Blog

Next-level engineering: implement systems and machines faster and more efficiently in the future

Next-level engineering: implement systems and machines faster and more efficiently in the future

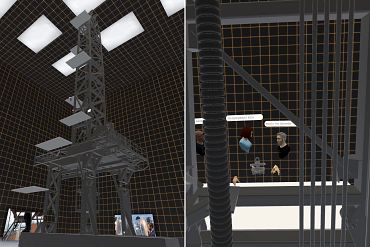

The iguverse allows for the next generation of engineering - simple, efficient and fast! A possible application scenario could look like this: "As an engineer, I would like to optimise our prototype production and make it more sustainable. I explore the iguverse, an engineering platform in the metaverse. With VR glasses I enter the virtual world of igus, work on projects digitally and network with colleagues to save time, money and CO₂ in order to clearly visualise problems and quickly work out solutions. I find 3D models for my applications in the right machine and industry world. Together with igus experts, I develop prototypes and carry out feasibility studies. Augmented reality helps me identify design flaws at an early stage. This also saves time, travel costs and resources. Colleagues and machine users can exchange ideas in the iguverse, practise and support service technicians with repairs."Working together today on solutions for the electrified vehicles of tomorrow

Joint simulation of assembly processes on the digital twin

More uses of the iguverse

In the iguverse, customers, engineers, project managers and decision-makers will come together in future as avatars in the digital space. They will carry out entire projects there, from the idea to the finished product - faster and more smoothly than is possible in the physical world alone.- Plan machines, systems and vehicles.

- Find the right components quickly.

- Develop products digitally with igus experts.

- Instruct customers or employees in handling machines.

- Get virtual assistance with repairs.

- Let 1:1 feasibility analyses with 3D models support you in product development.

- Identify weaknesses at an early stage and optimise your design - without physical prototypes.

- Present your company or your products on our platform and save yourself the effort of developing your own metaverse.

Would you also like to gain experience with virtual reality?

We are looking for beta testers for our iguverse! For an affordable fee, you can experiment with the digital parallel universe and convince yourself of the advantages - without having to bear the high costs for a VR infrastructure yourself.

Want to become a beta tester? Click the button below!

Become a beta tester

References about the iguverse

Metaverse: my first experience with the iguverse

Angela Struck, freelance journalist developmentscout: "In addition to Siemens and Deutsche Bahn, the Cologne-based plastics specialist igus is also experimenting with the industrial metaverse. The resulting digital parallel universes could have a disruptive effect on sales, engineering and service, just like the introduction of assembly lines or robotics once did. I went straight to the iguverse and felt like the leading lady in James Cameron's yet to be invented blockbuster Avatar Industry."To the article of developmentscout.com