180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

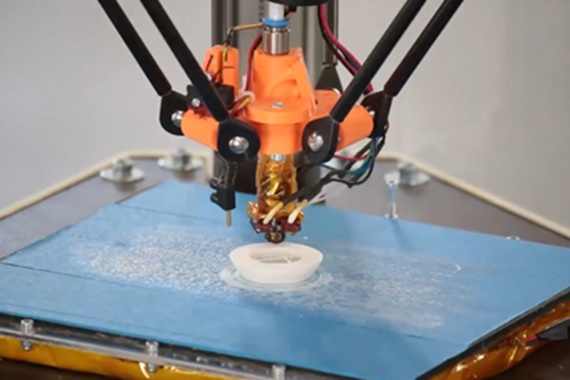

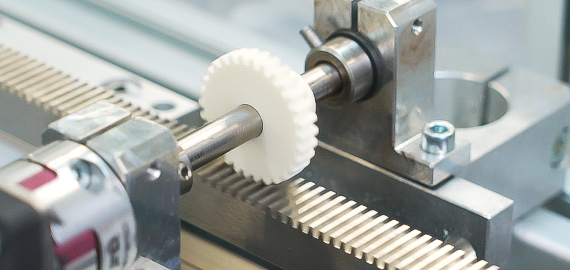

Our 3D-printed injection molds produce parts with similar material properties as components from conventional serial molds. With print2mold, igus® 3D prints injection mold tooling out of our engineered composite plastic iglide® materials, which are up to 80% cheaper than steel materials. We extensively test the tribological properties of our plastics inside our 41,000-square-foot lab in Cologne, Germany to ensure each material offers a longer service life than standard 3D-printing materials. All iglide® materials are low-wear, self-lubricating and maintenance-free. More than 50 iglide® plastics are available for printing injection molds.

Our 3D-printed injection molds produce parts with similar material properties as components from conventional serial molds. That’s because we extensively test the tribological properties of our iglide® plastics inside our 41,000-square foot lab in Cologne, Germany. This ensures that each part made from our materials will offer a longer service life than standard 3D-printing materials.

Monday to Friday from 8 am - 5 pm

24h