Change Language :

Ready-to-install energy supply systems streamline your production

Increase your factory's productivity and improve product quality with readychain®

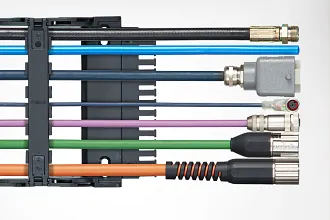

readychain® combines chainflex® cables and e-chain® cable carriers into a single, ready-to-install system. The entire procurement process is handled by igus®, and the complete system is delivered on a scheduled date. In addition, we provide on-site installation services as well as individual customer support.

readychain systems use a single PO and part number, making reordering a breeze and reducing processing time and costs. No need to keep track of part numbers for every single cable, connector, and chain being used.

Benefits:

- Harnessing time is reduced by up to 95%

- Reduction of manufacturing costs

- All components from stock

- One system, one part number

- Increased floor space

- On-site installation available

- Special designs are possible

Industries: Automotive, Robotics, EOT and Indoor Cranes, Port and Terminal Cranes, Material Handling, Oil and Gas, Shore Power, Aerial Lifts and Platforms, Steel Mills, Stage and Theater, Vertical Farming and more.

Browse readychain® products

readychain® Basic

- e-chain® with unharnessed cables

- Reduces installation time

- Reduces failures

readychain® Standard

- e-chain® with chainflex® assemblies

- No electrical termination needed

- No cable surplus

readychain® Standard+

- e-chain® with assemblies & mounting

- Optimized points of connection

- Ready to install, multi-axis system

readychain® Premium

- Optimized transport

- Optimized assembly

- Plug & Play

Installation and Inspection aka Orange Services

Proper installation is essential for the life of your cable carrier, and igus® has a team of dedicated engineers ready to assist you every step of the way. From site inspection, to installation, to complete modernization, our team will ensure the longest possible service life for your cable carrier system.

Contact us at (800) 521-2747 to discuss your project today!

Application Stories

Browse the Engineer's Toolbox

Frequently Asked Questions

igus e-chain® cable carriers are already being used reliably in hundreds of thousands of applications all over the world. From small devices up to steelworks, or very simple linear applications up to the most complicated task — igus offers thousands of options for all types of applications.

There are over 1,300 chainflex® cable types available from stock, each backed by an up-to 36-month, UL-verified service life guarantee. Our cable assemblies can be designed to meet over 20 different manufacturer standards, such as Siemens, Allen Bradley, and Beckhoff.

igus handles the entire procurement, assembly, and delivery process, ensuring your cable management system arrives on time and ready for integration. Whether you're automating packaging machines, gantries, machine tools, or production lines, our systems are designed for seamless plug-and-play installation.

Watch this video to see how readychain is assembledPre-assembled cable carriers are complete plug-and-play systems including an energy chain, chainflex® cables, and connectors—preconfigured and tested. With igus® readychain® systems, you can reduce installation time by up to 95% while eliminating integration risks.

igus® validates every component in its 3,800 m² test lab. Results from these tests are published and fed into the igus® service life calculator, allowing accurate lifespan predictions under real-world conditions.

Yes. igus® allows full customization—choose from 1,400+ chainflex® cable types, hundreds of energy chain styles, and connectors from all major manufacturers. Use the readycable and e-chain configurator to design your system. Contact your local sales representative to review your application.

All manufacturing industries such as automation, robotics, machine tools, packaging and other motion applications gain the most. These systems are ideal where uptime, predictable service life, and compact installation are priorities.

Yes. Nearly all chainflex® cables carry UL approval, CE conformity, and EAC certification. Many also comply with NFPA 79 and ISO Class 1 cleanroom standards, ideal for regulated or sensitive environments.

igus® supports connector brands like Harting, LAPP, TE, Phoenix Contact among others. Assemblies can include over molded, field-attachable, or hybrid connectors with customer-specific pinouts and labeling.

Custom solution lead times vary based on the complexity of the design.

Contact your local igus representative or product manager for current lead times.

igus® tests systems at speeds up to 10 m/s and accelerations to 50 m/s² across a range of bend radii, up to 70 million cycles. These parameters ensure readiness for high-performance, continuous-flex environments.

Yes. igus® chainflex® cables are rated for 10–100 million cycles depending on application. Browse tested cables on the chainflex® cable page by bend radius, speed, or voltage class.

igus® designs carriers with tight bend radii and optimized fill percentages, reducing system footprint. Custom bracket designs also help adapt to limited mounting space while protecting cables.

igus® customers typically reduce total system costs due to reduced design time, minimized rework, increased throughput, decreased logistics costs and faster installations. There’s also lower risk of miswiring or early failure.

Yes. igus® offers triflex® R robotic cable management with integrated chainflex® torsion-rated cables, retraction systems, and pre-pinned connectors for 6-axis robots.

igus® offers i.Sense condition monitoring and i.Cee predictive maintenance tools to track wear and prevent unplanned downtime through real-time analytics.

Every readychain® undergoes 100% electrical and mechanical QA. Tests include cable continuity, pinout validation, strain relief integrity, and visual inspection. Documentation is available on request. All cable and wire harness assemblies are made to IPC/WHMA-A-620E standards.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert