Change Language :

Bearings, shafting, linear guides, and cable carriers for the agricultural industry

Design efficient and long-lasting agricultural machinery with highly engineered, maintenance-free plastic components from igus®. Our durable iglide® bearing materials, embedded with solid lubricants for dry-running operation, can absorb high shock and impact loads. They’re also resistant to dirt, chemicals and corrosion.

Customer Applications

Bearings & Shafting for Agricultural Machinery

Not sure which material would be best for your application? Request a free heavy duty bearings sample box, which includes one of each of the bearings below.

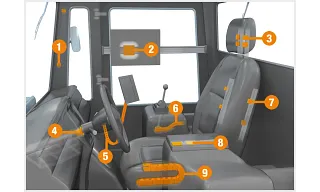

Components for Driver's Cabins in Agricultural Machinery

- Mirror adjustment: iglide® J plain bearing

- Monitor adjustment: drylin® W guide carriages

- Headrest adjustment: drylin® W linear guides

- Steering column: iglide® G plain bearing

- Operating elements: triflex®

- Hydraulic valve connection: igubal® spherical bearing

- Seat back adjustment: drylin® W linear guides

- Armrest adjustment: drylin® W linear guides

- Seat adjustment: E2 e-chain® and chainflex® cables

Cable Carriers for Agricultural Machinery

Browse the Engineer's Toolbox

Contact Us

Questions or product information? Please contact:

igus® Canada Inc.+1 800 965 2496Contact an Expert

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert