180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

A:

Corrugated hose:

Stretches greatly under tensile load. The cables in the corrugated hose cannot elongate in the same ratio and are therefore damaged.

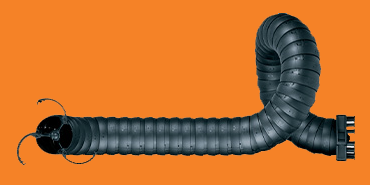

triflex® R:

Stretches only minimally under tensile load. No additional load for the cables

A:

Corrugated hose:

It offers no minimum bend radius

triflex® R:

Offers a bend radius of between 50 to 182mm depending on the triflex size.

A:

Corrugated hose

Damage to the corrugated hose due to stresses and torsional movement can cause damage to the cables

triflex® R:

The stop-dogs prevent the e-chain from bending too tightly.

A:

Corrugated hose:

None or limited torsion occurs

triflex® R: 7-12.5° torsion angle per chain link

Up to 900° torsion angle for one metre (example: TRC/TRE.40)

A:

Corrugated hose:

If the plug is not too large, the cable can be pushed through from the ends.

triflex® R: With TRE, TRL, TRLF and TRCF, cables with plugs can be pressed in externally.

A:

Corrugated hose:

Can be shortened only with tools (knives). This can pose health and safety risks and can damage cables.

triflex® R:

Length is adjustable with and without tools being required. This is dependant on which triflex range.

Due to the moduar design, the triflex can be lengthened and shortened by fitting/ removing chain links to suit. This cannot be done with a corrugated hose.

A:

Corrugated hose:

Can be installed via the hose ends only.

triflex® R: Can be installed via the e-chain ends or due to the design of the TRE, TRL and TRCF, the installing of cables/services can be implemented externally.

A:

Corrugated hose:

Damaged areas cannot be replaced or repaired.

triflex® R: In the unlikely event that a chain link is damaged, the damaged chain link can be replaced, even when the chain is filled with cables or services.

Whether you're interested in end-to-end, fully assembled solutions or looking to build your own customizable project, let us assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 965-2496 to discuss your project today!