Professional Stage Rigging Systems

Find the Best Motion Plastics Products for Stage Rigging Systems

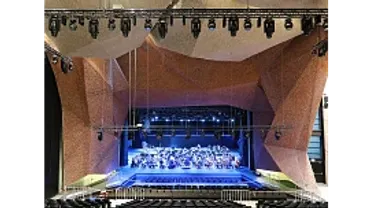

For an event to be a success without technical breakdowns, machine components that work reliably and quietly are needed. Our energy supply systems and plain bearing products do exactly that and are also maintenance-free and lightweight. We have special energy chain solutions ready for any type of movement, but especially vertical movements, such as those for lighting hoists and holding devices, movable gantry bridges, video screens, stage podiums, and loudspeakers. Our energy chains safely guide cables for the stage lighting, sound, video, building services, and drive technology.

Benefits igus stage rigging systems:

- Data and energy guided safely and reliably

- Trouble-free operation

- Quiet and low-vibration

- For smallest bend radii and installation spaces

- Robust and easy to install

Contact an expert

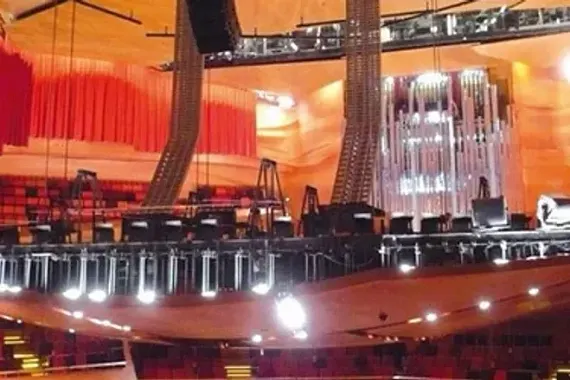

Vertical lighting hoist, portal bridges, and video cube movement

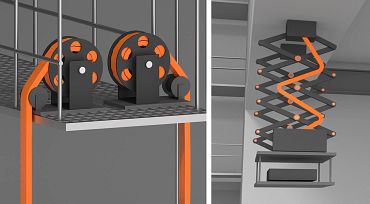

If lighting hoists, video walls, projectors, chandeliers, or loudspeakers move vertically on the stage or in the auditorium, the cable package must also be guided safely. If the system is not to be seen or if its weight prevents it from being transported, our e-spool cable drum without a slip ring is ideal. Otherwise, the zig-zag system is a good alternative.

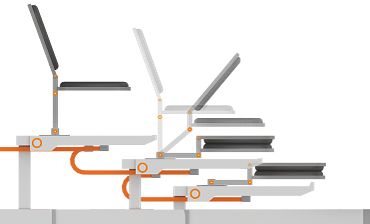

Scissor lift stage platform

If stage podiums move up and down, all associated cables for the drive, media, and lighting technology must move with them. Thee-spool allows energy chain deflections. The zig-zag system is used to supply the follow-up podium with the necessary cables. Maintenance-free iglide Q3E heavy-duty plain bearings and drylin W linear guides are used for scissor lift podiums.

White Paper: Vertical chain hoists in stage rigging

Horizontally moving portal towers

In order to change the portal section, the portal towers in theatres can often be moved. Since the towers are equipped with technology, safe energy supply is necessary. This is where our E4.1-series e-chains come in. The chain either moves in a trough below the work gallery or hangs freely in a U-shape on the tower.

Curtain scissor hoist

Scissor hoists are used to open and close curtains evenly, especially with heavy fabrics. iglide G plain bearings and thrust washers are used in the joints. If the drives for horizontal opening also move, the zig-zag system is a good solution for safely guiding the cables.

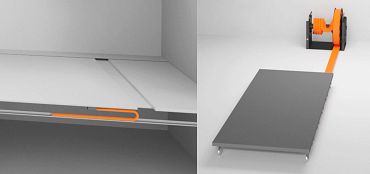

Linear guidance of the cable drum or deflection rollers in drive systems

If the cable drum for stage machinery winches is very close to the first guide roller, the cable drum or guide roller must be moved in parallel. This ensures that the steel cables are always safely guided when they are wound on and off the drum. Our lubrication-free drylin W and drylin R linear guides or a drylin linear axis with lead screw drive are usually used here. When they are moving, the cables are also securely guided in an E2.1 energy chain. xiros conveyor rollers guide the cables on the drum.

Horizontal stage trolley movement

Energy chains ensure a safe power supply for moving horizontal elements on the stage such as stage trolleys and LED video walls. Our noise-reducing E6-series e-chains or thee-spool cable drum are suitable for this application.

Telescoping galleries

In telescoping spectator galleries, cables for the step lighting must be moved by such means as E2.1 or E4Q e-chains. Our maintenance-free plastic slide bushes made from iglide G or iglide J are ideal for the bearing points in the seat tilting mechanism.

Products for camera technology

Our lubrication-free plain bearings and linear technology components in combination with energy chains for linear and 3D movements ensure that camera dollies, camera sliders, and camera cranes move quietly and without vibration and that cables are guided compactly and safely.

Stage Rigging Customer Applications

We have been able to help many customers improve the movement of their event technology. Browse through our customer projects that use our energy chain systems, flexible cables, and plain bearings: moving seating and stage podiums, stage sets, acoustic and lighting systems, camera robots, and complex multimedia installations.

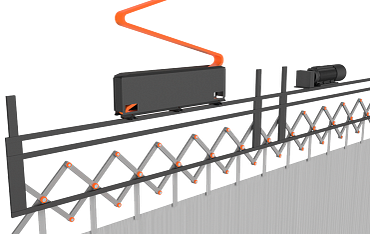

Movable stage platforms

Stage platforms are used in theatres and concert halls all over the world. Since space under the stage is very limited, the data and power cables must be guided safely and reliably. This can be achieved using igus zig-zag e-chains, which are housed in space-saving narrow metal containers.

Robotic camera in news studio

Smooth running, low level of vibration and high wear resistance are important criteria for the individual components of studio equipment. Camerobot Systems GmbH from Germany uses igus series E6 energy chains to guide the robotic systems in the news and television studio.

Efficient and Safe Theatrical Rigging for Modern Event Halls

Stage lighting rigging with spring cable drums for a movable nightclub ceiling

Moveable ceiling construction above the stage

Zig-zag e-chains from igus are used in this application. This system allows a creative solution for vertically suspended applications, which is not only cost-effective but also space-saving and "inconspicuous".

Stage Rigging Systems FAQs

Q: What are the main types of stage rigging systems?

The main types of stage rigging systems include:

1. Manual counterweight systems Motorized rigging systems

2. Each type offers different benefits in terms of cost, control, and complexity.

3. Automated computerized systems

4. Hemp rigging (rope sets)

5. Hybrid systems (combining manual and automated elements)Q: How do vertical energy chains improve stage rigging?

Vertical energy chains enhance stage rigging by:

1. Organizing and protecting cables during movement

2. Reducing wear and tear on electrical components

3. Allowing smooth operation of moving set pieces

4. Minimizing the risk of cable entanglement

5. Facilitating easier maintenance and cable replacement

6. Improving the overall aesthetics of the rigging systemQ: What is a counterweight rigging system and how does it work?

A counterweight rigging system:

1. Uses weights to balance the load of suspended equipment

2. Consists of a rope, pulleys, arbor (weight holder), and batten

3. Allows manual operation with minimal effort

4. Provides precise control for smooth movements

5. Requires regular inspection and balancing Is common in traditional theater settingsQ: What are the advantages of motorized rigging systems?

Advantages of motorized rigging systems include:

1. Increased lifting capacity for heavier loads

2. Precise and repeatable movements

3. Reduced physical labor for operators

4. Enhanced safety through built-in limit switches

5. Ability to handle complex cue sequences

6. Faster scene changes and set transitions

7. Improved energy efficiency with modern motors

Q: How do you maintain and inspect stage rigging systems?

Maintaining stage rigging systems involves:

1. Daily visual inspections before use

2. Weekly functional checks of all moving parts

3. Monthly detailed inspections of cables, connections, and wear points

4. Annual comprehensive inspections by certified professionals

5. Immediate replacement of worn or damaged components

6. Regular lubrication of moving parts

7. Keeping detailed maintenance logsQ: What safety features are essential in modern stage rigging systems?

Essential safety features in modern rigging systems:

1. Load cells for real-time weight monitoring

2. Redundant braking systems

3. Emergency stop buttons at multiple locations

4. Overtravel limit switches

5. Slack line detection sensors

6. Automated fault detection and reporting

7. Backup power systems for controlled emergency loweringQ: How do you choose the right stage rigging system for your venue?

Factors to consider when choosing a rigging system:

1. Venue size and layout

2. Types of productions typically hosted

3. Available budget for installation and maintenance

4. Existing infrastructure and power capabilities

5. Required load capacities and speed of operation

6. Level of automation desired

7. Local building codes and regulations

8. Expertise level of available operatorsQ: What is the "zig-zag" system in stage rigging?

The "zig-zag" system in stage rigging:

1. Uses a folding pattern for cable management

2. Allows for compact storage of cables when retracted

3. Provides smooth extension and retraction of cables

4. Reduces stress on cables during movement

5. Is ideal for applications with limited space

6. Can be used in both vertical and horizontal setups

7. Enhances the lifespan of cables and connectors

"The products (energy chains and chainflex cables) offered us a reliable solution for connecting the fixed supply points on the ground to the moving platforms. The special cables allow flexible movements without damage and extend maintenance intervals."

- Attila Lukacs, GEPBER-Szinpad Kft.

"During our discussions, the igus sales representative drew our attention to the e-spool flex solution."

- MECAoctet

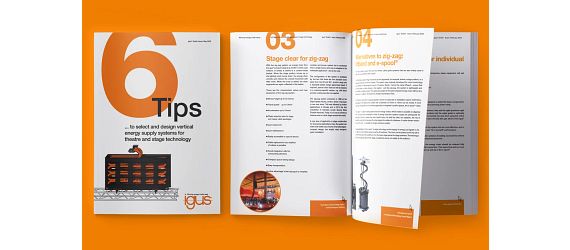

Brochure:

Explore Our Brochure for Cutting-Edge Solutions in the Stage rigging Industry!

Discover silent, maintenance-free solutions that will keep your shows running smoothly. Download our theater industry catalog now and take the first step towards more reliable, cost-effective stage equipment.More professional stage rigging equipment resources

Stage lighting equipmentMaintenance-free bearing technology and quiet e-chains for spotlights, lasers, and other light effect devices