Successful stage rigging equipment applications

Stage Rigging Equipment Solutions

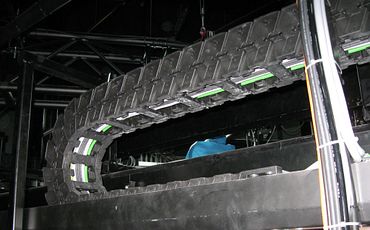

Used for stage construction, lighting systems and audio equipment, igus® products can help you enhance the technical functionality of your application while saving money. igus® products made of high-performance plastics are self-lubricating, maintenance-free and lighter than conventional solutions. In many cases, they are suitable for use where space is at a premium, whilst being quiet and exhibiting very low vibration. We will be happy to help find the right solution for you."The products (energy chains and chainflex cables) offered us a reliable solution for connecting the fixed supply points on the ground to the moving platforms. The special cables allow flexible movements without damage and extend maintenance intervals."

- Attila Lukacs, GEPBER-Szinpad Kft.

"During our discussions, the igus sales representative drew our attention to the e-spool flex solution."

- MECAoctet

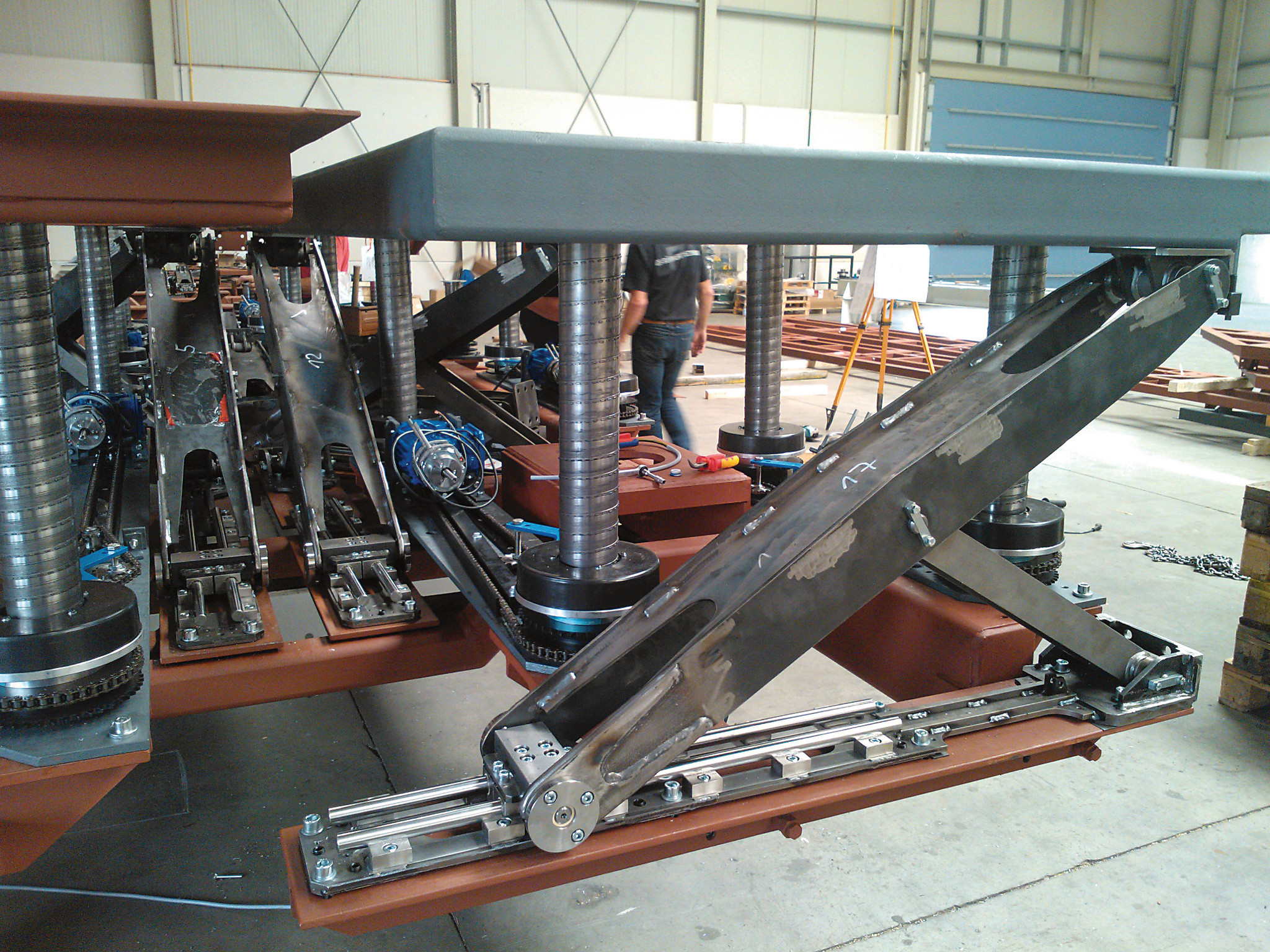

e-chains and cables for moving seated podiums in Budapest's multi-purpose hall

Cable guidance for challenging multimedia installation in Moscow's GES-2 auditorium

Various energy chain systems ensure safe cable guidance in Waagner-Biro stage technology

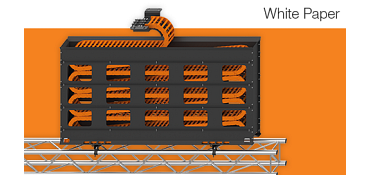

White Paper: Vertical chain hoists in stage rigging

Smooth-running energy chains for Tagesschau studio camera robots

Browse the CA Blog & Toolbox

Stage lighting overview & guide

Tips to select and design vertical energy supply systems for stage lighting

One-of-a-kind performing arts center made possible with e-chain

Space-saving guidance system for all media at the Cologne Opera

Safely moved lighting trusses at the Cultural and Congress Centre in Toruń (Poland)

Quiet stage podium adjustment with maintenance-free linear guides

.jpg?h=230&crop=yes&keep=s&w=370&quality=80)

Stage Rigging Equipment FAQs

Q: What are the essential pieces of stage rigging equipment?

Essential stage rigging equipment includes:

1. Trusses: For supporting lights and scenery

2. Hoists: For lifting and lowering equipment

3. Pulleys and blocks: For redirecting lift lines

4. Shackles and turnbuckles: For secure connections

5. Safety cables: For secondary fall protection

6. Control systems: For managing motorized elements

7. Load cells: For monitoring weight distribution

8. Energy chains: For organizing moving cablesQ: How do you ensure proper load distribution in stage rigging?

To ensure proper load distribution in stage rigging:

1. Calculate total and point loads accurately

2. Use load cells for real-time weight monitoring

3. Implement appropriate spreader bars or bridles

4. Balance loads across multiple support points

5. Adhere to manufacturer's weight limits for all equipment

6. Regularly inspect and maintain all rigging components

7. Employ certified rigging professionals for complex setups

8. Use computer-aided design tools for precise planningQ: What types of hoists are used in stage rigging and how do they differ?

Types of hoists used in stage rigging:

1. Manual chain hoists: For simple, low-cost lifting

2. Electric chain hoists: For frequent, heavy lifting

3. Wire rope hoists: For smoother, quieter operation

4. Pneumatic hoists: For explosive environments

5. Motorized winches: For precise control of large set pieces

6. Hydraulic hoists: For high-capacity lifting in limited spaces

Each type offers different benefits in terms of capacity, speed, and control.Q: How do you choose the right truss system for your stage?

Factors to consider when choosing a truss system:

1. Load capacity required

2. Span length needed

3. Type of productions (permanent vs. touring)

4. Ease of assembly and disassembly

5. Compatibility with existing equipment

6. Material (aluminum vs. steel)

7. Budget constraints

8. Local regulations and safety standards

Q: What are the key safety considerations for stage rigging equipment?

Key safety considerations for stage rigging equipment:

1. Regular inspection and maintenance schedules

2. Proper training for all personnel

3. Use of appropriate personal protective equipment (PPE)

4. Adherence to load capacity limits

5. Implementation of redundant safety systems

6. Clear communication protocols during rigging operations

7. Proper documentation and record-keeping

8. Compliance with industry standards and local regulationsQ: How do you maintain and inspect stage rigging equipment?

Maintaining and inspecting stage rigging equipment:

1. Conduct daily visual inspections before use

2. Perform weekly functional checks on moving parts

3. Schedule monthly detailed inspections of cables and connections

4. Arrange annual comprehensive inspections by certified professionals

5. Replace worn or damaged components immediately

6. Lubricate moving parts according to manufacturer specifications

7. Keep detailed maintenance logs for all equipment

8. Train staff on proper handling and storage proceduresQ: How is sustainability being addressed in entertainment rigging?

Control systems in modern stage rigging:

1. Enable precise movement and positioning of equipment

2. Allow for programmable cues and sequences

3. Integrate with lighting and sound systems for synchronized effects

4. Provide real-time monitoring of load weights and distribution

5. Offer emergency stop functions for enhanced safety

6. Allow for remote operation and troubleshooting

7. Store and recall multiple show configurations

8. Facilitate more complex and dynamic stage designsQ: How do you select the right cables and connectors for stage rigging?

Selecting cables and connectors for stage rigging:

1. Consider the required load capacity and safety factor

2. Choose appropriate materials for the environment (indoor vs. outdoor)

3. Ensure compatibility with existing equipment

4. Select the correct size and type for the application

5. Consider flexibility needs for moving components

6. Choose connectors with secure locking mechanisms

7. Opt for high visibility colors for safety

8. Ensure compliance with relevant safety standards

Brochure:

Explore Our Brochure for Cutting-Edge Solutions in the Stage rigging Industry!

Discover silent, maintenance-free solutions that will keep your shows running smoothly. Download our theater industry catalog now and take the first step towards more reliable, cost-effective stage equipment.Stage Rigging Solutions

Stage Lighting Equipment

Stage and Theater Overview