Functionally reliable even in typhoon storms

Shanghai: Energy supply systems for shipyard cranes successfully in use since years

At the southern port of Shanghai's Pudong area, at the mouth of the Yangtze River, the Waigaoqiao Shipbuilding Co. Ltd. (SWS) is situated just opposite the Changxingdao port area. The Chinese shipbuilder SWS is one of the ten largest worldwide. Three shipyard cranes are currently in operation in this huge industrial area, the dimensions of which correspond to those of 30-storey high-rise buildings. The energy and data supply to the gigantic lifting elements is implemented with plastic energy chain systems from igus.Profile

- What was needed: Roller energy chains in steel guide troughs, chainflex cables, push/pull force detection i.Sense EC.P

- Requirements: High corrosion resistance due to aggressive environmental conditions (rain, wind, salt water)

- Industry: Shipbuilding

- Success for the customer: On-site consultation, installation and acceptance of the energy chain systems, regular testing

Problem

Waigaoquiao Shipbuilding Co. Ltd. (SWS) was faced with the task of finding a suitable solution for the energy and data supply for the gigantic lifting elements for three shipyard cranes. Due to the special location, the expectations and performance requirements of an appropriate solution were particularly high. At the huge port facility, which is located at the mouth of the Yangtze River, just opposite the Changxingdao port area, there are not only weather influences such as rain, but also whipping winds and the effects of salt water most of the time. These extreme influences are accompanied each year by a two-month rainy season, which poses an additional risk of corrosion and an additional challenge to the energy supply system. In order to avoid plant downtimes, the aggressive ambient conditions had to be countered with a highly functional and reliable response.Solution

After energy chain systems from igus were installed on over 180m of travel in 2001, they have been running trouble-free ever since, something that even a typhoon could not change a few years ago. The energy and data supply of the shipyard cranes and the 32-tonne material crane is provided by low-friction roller energy chains in igus guide troughs made of steel. The chains are designed for high cable loads and long travels, even at high speeds.In the energy chains, chainflex cables are used. Thanks to their highly wear-resistant TPE outer jacket, they also withstand extreme conditions. The cables are resistant to UV radiation, to corrosion by coolants, lubricants and organic oil and withstand temperatures from -35°C to +100°C.Our push-pull force detection system (i.Sense EC.P) was also installed on this large-scale plant. Also called "PPDS" (Push/Pull Force Detection System), it monitors the displacement forces of the energy chains online to prevent damage to the system as well as failures due to preventive maintenance or remote intervention.Zhang Quan, Head of the SWS Development Department

Application examples with smart plastics

smart examples with e-chain®, chainflex® cables and bearings

Industry: Automotive

Intelligent Breakage Monitoring in 22 Ton Driving Simulator

Which smart plastics technology is used?

P4.1 roller chain, i.Sense EC.B, chainflex cables

Why is it used?

Increase in plant safety and availability; complete project implementation from a single source; smart early warning system.

Industry: Crane

Longest travel with smart roller chain system

Which smart plastics technology is used?

i.Sense EC.P for permanent monitoring of the system

Why is it used?

The system includes intelligent sensors for monitoring the pull/push forces, which can be used for an emergency shutdown in the event of increased forces.

Industry: Crane

Smart shipyard cranes in successful use for years

Which smart plastics technology is used?

Roller energy chains with the iSense EC.P pull/push force detectio.

Why is it used?

To avoid system damage and failures through preventive maintenance or remote intervention.

Industry: Crane

Complete smart plastics package on RMG crane

Which smart plastics technology is used?

EC.P for push/pull forces, EC.B for chain breaks, CF.P for measuring tensile force on cables, EC.M for movement data and EC.W for measuring abrasion and a predictive maintenance system.

Why is it used?

The customer now has full control, overview and safety.

Industry: Automotive

Austrian automotive parts supplier uses smart plastics

Which smart plastics technology is used?EC.B sensor for breakage monitoring + EC.W for measurement of the abrasion along the e-chain®.

Why is it used?

For the customer, it is important that subsequent damage to the equipment be prevented in the event of chain breakage.

Industry: Transport

Predictive maintenance in train washing station

Which smart plastics technology is used?EC.M motion sensor, EC.W abrasion sensor, EC.B breakage sensor, i.Cee:plus to evaluate data, i.Cee:net to transfer to dashboard.

Why is it used?

The built-in components ensure that, if damage occurs, the machine is shut down to provide an optimum maintenance plan.

Industry: Packaging

"igus® CF.Q condition monitoring can prevent failure of machines with high output"

Which smart plastics technology is used?

E4.1L e-chains® and chainflex® cables pre-assembled as a readychain, CF.Q isense sensors, Module Connect connector.

The isense sensors with CF.Q module detect core ruptures before they occur and save the user high downtime costs.

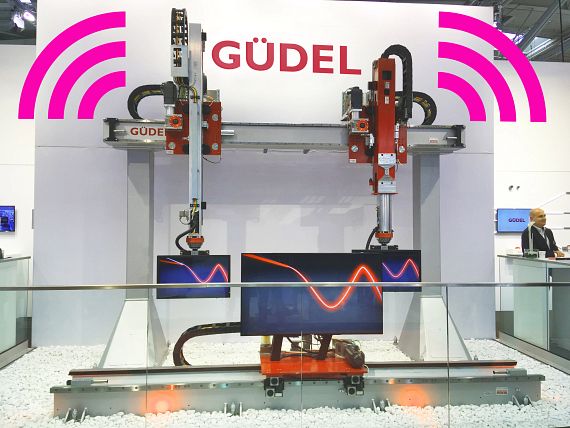

Industry: Robotics

Predictive maintenance planning for linear robot

Which smart plastics technology is used?

EC.M sensor for motion data and EC.W sensor for the measurement of abrasion along the energy chain

The two sensors transfer the measured values via the i.com module (now i.Cee module) directly to Güdel's condition monitoring system, which evaluates the data and makes maintenance predictable.

Industry: Mining

Smart plastics in aluminum oxide production

Which smart plastics technology is used?

EC. P System as a cleaning or maintenance reminder.

Why is it used?

The heavy dust arising during the movement of bauxite is an enormous stress, especially for moving machine components.

Industry: Wastewater and sewage treatment plants

Smart sensors in sewage treatment plant pipelines prevent failures before they occur.

Which smart plastics technology is used?EC. P pull force monitoring system for the energy chain

Why is it used?

The EC. P module is used to shut down the plant in an emergency so that the damage can be rectified or total damage is avoided.

Industry: Agriculture

Smart bearings in agricultural machinery

Which smart plastics technology is used?i.Sense bushing

Why is it used?

The smart bearings reports the current condition of components and how worn they are.

Smart e-chain® and cables

Use smart plastics to stay abreast of how your chain is doing.

Our intelligent e-chain® systems are already reliably in use in hundreds of thousands of applications worldwide - from beverage machines and CNC machines to steel mills.Smart bearing technology

Don't let a defective plain bearing ruin your day.

Smart plain bearings are great for sensitive or hard-to-reach spots on a machine, since they allow the bearing's condition to be assessed at any time.Smart Applications