Drag Chains for Double Girder Overhead Cranes

Enhancing Efficiency in Double Girder Overhead Cranes

Double girder overhead cranes are particularly flexible crane types that ensure the lifting and transport of high loads, especially in warehouses or production halls. Due to the wide range of applications of the systems, a tailor-made energy supply solution is required depending on the application. Our energy chains, guide troughs and cables are also designed for quick retrofitting, quiet movement and the smallest bending radii.

Advantages of igus crane girder products:

- Low noise and vibration

- Less installation space and weight

- Lifetime calculation

- Fast delivery

- Easy installation

- Cost-effective and low maintenance

- Complete system or individual components from batch size 1

White Paper:

Efficient energy supply for overhead bridge crane

- Advantages and disadvantages of energy chain systems and cable festoon systems for steelworks cranes

- The most innovative solution for cranes for steel plants

- Future technologies: roller energy chains

Shop double girder overhead crane parts and functions

Energy chain system E4.1

- More stability with smaller dimensions

- Long service life even under abrasive environmental conditions

guidefast guide rail

- Lateral attachment to the crane girder

- Easy installation, up to 80% time savings compared to conventional guides

E4.1L energy chain system

- Combines the stability of the E4.1 with the accessibility of the E2/000

- Reduced weight

E4Q energy chain system

- Especially suitable for self-supporting and long travel distances

- Save installation time and costs through tool-free opening and closing

E4.1R energy chain

- Optionally rolling or sliding

- For use on cranes with not so high additional loads

- Noise and vibration reduced

Guide troughs

- U-shaped steel guide troughs for the E2 mini energy chains (series 10 and B15) and zipper chain (series 15) energy chains

- Outer height of trough side part: 48mm

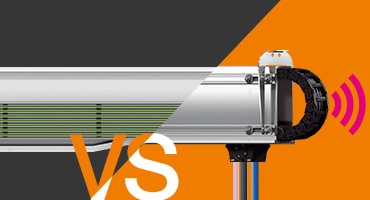

Condition monitoring | i.Sense

- Non-stop condition monitoring

- In the event of problems, the software can initiate an emergency stop to avoid damage

- Increases operational safety

Cables for moving applications

- Cables for moving applications

- With up to 4 years warranty

- E.g. motor cables CF34 and CF35 with improved temperature stability

Floating moving end

- As compensation in the case of long travels

- Small, lightweight and cost-effective

- Compatible with isense EC.P

- Can be used for various energy supply systems

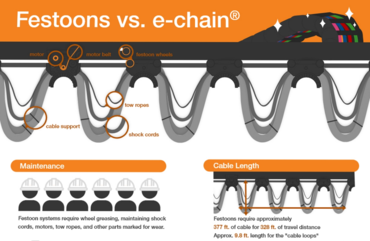

Cable Festoon System Infographic:

The Challenges of Cable Festoon Systems

Cable festoon systems have been a staple in crane operations for many years, but as demands for faster installation, increased flexibility, and improved technology have grown, the drawbacks of cable festoon systems have become apparent.Indoor crane system examples

View all successful applications in the crane industry

Heat and dust: energy chains for a Double girder EOT crane in adverse conditions

In Thyssen Krupp’s Duisburg hot rolling mill, a slab transport crane from BANG Kransysteme GmbH & Co. KG is responsible for handling the slabs at the interface between the steelworks and the rolling mill - in heat and dust. The supply of energy and signals to the trolley and cab is ensured by heavy-duty igus energy chains supplied pre-assembled as basic readychain systems.

Crane in cement plant

Chemical-resistant indoor crane

Indoor crane in metal processing

Overhead Bridge crane in steelworks

This crane transports billets in a steel mill using a magnetic beam. For the power supply of the slewing gear, the developers are using a triflex series e-chain instead of the previous conductor rail.

Overhead Gantry crane in concrete plant

In the harsh environment of concrete processing, energy supply systems contribute to the stability and reliable function of indoor cranes.

Double girder bridge crane track in waste incineration plant

In the Eschweiler waste incineration plant, the existing trailing cables were replaced by an energy chain that was developed for use under adverse environmental conditions.

Double girder gantry crane: 50% more storage space

Indoor cranes in the foundry

Containers containing liquid metal are transported in a foundry using these three cranes. The hot environment and high levels of contamination placed severe demands on the cable guidance.

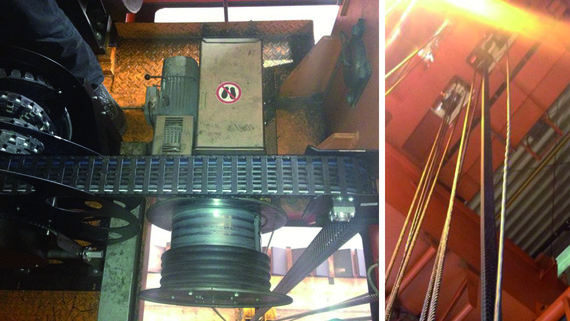

Coil crane in steelworks

In this coil crane, the motor-driven cable drums required a high level of maintenance. That is why they were replaced by our e-spool system.

guidefast system for gantry crane

The manufacturer Piedmont Hoist and Crane in the USA opted for the convenient guidefast modular guide trough system for a gantry crane.

Double girder vs single girder crane

Single girder cranes have one bridge beam, making them cost-effective, lighter, and simpler to install and maintain. Double girder cranes, with two bridge beams, offer higher load capacities, greater hook height, and the ability to incorporate more features like walkways and cabs. They are suitable for heavy-duty applications and environments requiring higher lifting and longer spans

FAQ-Frequently Asked Questions

Q: What are the advantages of a single girder cranes?

- Cost-Effective: Single girder cranes use fewer materials and have a simpler design, reducing costs.

- Efficient Use of Space: Ideal for areas with limited vertical space, offering superior hook approaches.

- Easy Installation and Maintenance: Simpler structure makes them easier to install, service, and maintain.

- Lower Building Load: Reduced deadweight means less structural support is needed

Q: What are the disadvantages of single girder cranes?

- Limited Capacity: Typically up to 15-20 tons, not suitable for very heavy loads.

- Lower Hook Height: The hoist under the girder limits lifting height.

- Fewer Features: Adding components like walkways or cabs can be challenging and costly

Q: When should you choose a single girder crane?

Choose a single girder crane if you need a cost-effective solution for light to moderate loads, have limited vertical space, and require a crane that is easier to install and maintain. They are suitable for workshops, warehouses, and smaller manufacturing facilities

Q: What is the maximum load capacity for a single and double girder crane?

Single girder cranes typically handle up to 15-20 tons, while double girder cranes can lift up to 500 tons, making them suitable for more demanding industrial tasks

Q: What are the advantages of a double girder crane?

- Higher Load Capacity: Can lift heavier loads, often up to 500 tons.

- Greater Hook Height: The hoist can be placed between or on top of the girders, providing more lifting height.

- Versatility: Can accommodate additional features and are suitable for both indoor and outdoor use.

- Stability and Safety: Better for frequent heavy lifting and offers enhanced stability.

Q: What are the disadvantages of a double girder crane?

- Higher Costs: More materials and complex design increase initial costs and setup.

- Space Requirements: Requires more overhead space and additional structural support.

- Complex Maintenance: More sophisticated components can demand specialized maintenance

Q: When should you choose a double girder crane?

Opt for a double girder crane when you need to lift heavy loads, require greater hook height, or need to incorporate additional features like walkways. They are ideal for heavy-duty applications such as mining, steel production, and large manufacturing plants.

Q: How do double girder vs single girder cranes compare in terms of cost and performance?

Double girder cranes are more expensive due to higher material and installation costs but offer better performance for heavy-duty applications. Single girder cranes are cost-effective for lighter loads and simpler maintenance, making them ideal for smaller operations.

System comparison

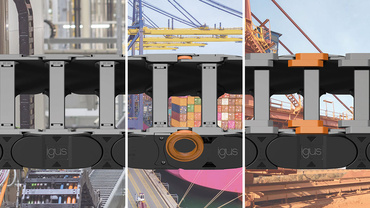

Energy chain systems instead of festooning, motor cable drums and busbars

Provide guidance for cables and energy chains while keeping them protected and safe in wind and fluctuating temperatures, minimizing downtime.

No slip ring on long travels. Guide all media safely in one system. Travels of up to 1,000 metres.

Deliver data, energy, fluids and air safely in a single energy chain system. For narrow compact spaces and fast lane movement.