Change Language :

Resistant to Cold, Dirt & Vibration...

igus® motion plastics® for heavy duty machines

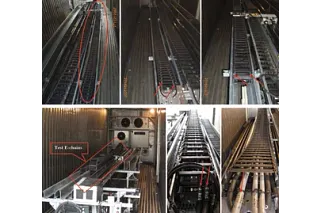

igus® Energy Chains guide cables and hoses though a variety of different movements on cranes, machine tools and heavy equipment. For applications in cold weather environments, we offer a wide range of heavy duty products that can stand up to these harsh conditions. igus® has provided solutions for many of these types of applications, from small micro chains on sensitive laboratory devices up to heavy duty long travel carriers for large mining equipment. We also conduct several thousand tests per year in our test laboratory to guarantee successful operation of our products under these cold weather conditions.

Tested...in the largest lab of its kind, igus® Cologne

Costs down - service life up!

3,000 tests per year

igus® operates the largest test lab in our industry. On more than 18,840 sq. ft. of floorspace, we conduct the following each year:

Two billion test cycles for highly flexible cables

One million electrical measurements

15,000 tribology tests (friction and wear)

Vibration test

**Reason for the test:**A customer had a problem with a steel cable carrier, since vibrations caused screws to loosen, causing the guide to become unstable.**Test setup:**A vertical igus® E4 e-chain® was exposed to direct vibration (comparable to a rock drilling machine).**Result:**No damage to the connections on the e-chain® links. No individual parts were lost.

Cold test

**Reason for the test:**To determine maximum service life of igus® chainflex® TPE cables at temperatures of -40°F (-40°C).**Test setup:**A CF35 TPE cable was moved in an e-chain® in the igus® climate container at a travel of 23 ft. (7 m) and a speed of 4.92 f/s (1.5 m/s) at -40°F (-40°C).**Result:**The test was ended after 3.7 million cycles. The cable exhibits little / no wear and is fully functional.