Change Language :

iglide® A200 - Material data

| General features | Unit | iglide® A200 | Test method |

|---|---|---|---|

| Density | g/cm3 | 1.14 | |

| Color | White | ||

| Max. humidity absorption at 73 ° F/50% R. H. | Wt.-% | 1.5 | DIN 53495 |

| Max. water absorption | Wt.-% | 7.6 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.10 - 0.40 | |

| p x v value, max. (dry) | psi x fpm | 2900 | |

| Mechanical properties | |||

| Modulus of elasticity | psi | 362,500 | DIN 53457 |

| Tensile strength at 68 ° F | psi | 16,820 | DIN 53452 |

| Compressive strength | psi | 7,830 | |

| Permissible static surface pressure (68° F) | psi | 2,610 | |

| Shore D hardness | 81 | DIN 53505 | |

| Physical and thermal properties | |||

| Max. long-term application temperature | °F | 176 | |

| Max. short-term application temperature | °F | 338 | |

| Min. application temperature | °F | -40 | |

| Thermal conductivity | [W/m x K] | 0.24 | ASTM C 177 |

| Coefficient of thermal expansion (at 73 °F) | [K-1 x 10-5] | 10 | DIN 53752 |

| Electrical properties | |||

| Specific volume resistance | Ωcm | > 1013 | DIN IEC 93 |

| Surface resistance | Ω | > 1012 | DIN 53482 |

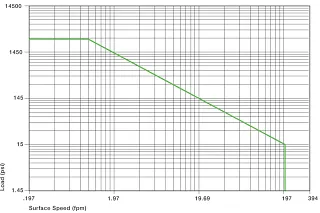

Permitted p x v values

For iglide® A200 plastic bushings with 0.03937 (1 mm) wall thickness in dry operation against a steel shaft, at 68 ° F, installed in a steel housing.

Plastic bushings made of iglide® A200 are suitable for application in direct contact with foodstuffs. Hence they are the ideal solution for bushing positions in machines for the food industry, medical equipment manufacturing, for small equipment for households, etc. As the admixture of lubricants should be foregone in favor of food compatibility, the thermoplastic composition of iglide® A200 is particularly adjusted for abrasion resistance. In addition the iglide® A200 is characterized by its capacity to embed dirt and by its quiet operating behavior.

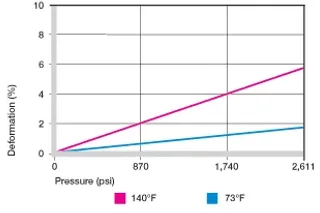

Figure 8.2: Deformation under load and temperatures

Compressive Strength

The high abrasion resistance, the insensitivity to dirt and the ability to operate dry enable it to dispense with the otherwise complex casings for lubricated bushings. Figure 8.2 shows the elastic deformation of iglide® A200 with radial loads. Under the maximum recommended surface pressure of 2610 psi, the deformation amounts to less than 2%. A plastic deformation is negligible up to this radial load. It is however also dependent on the period of exposure.

Permitted surface speeds

iglide® A200 is developed for low surface speeds. Maximum speeds up to 157 fpm(rotating) and 393 fpm (linear) respectively are permitted for continuous application in dry operation. These specified values state the limits to which the long-term permitted temperature rises due to frictional heat. In practice these limit values are not always reached due to interactions.

| fpm | rotating | oscillating | linear |

|---|---|---|---|

| Constant | 157 | 118 | 393 |

| Short-term | 295 | 216 | 590 |

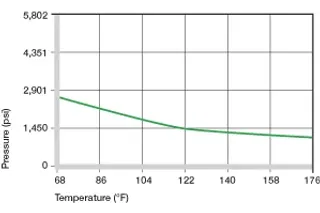

Figure 8.3: Maximum recommended surface pressure dependent on the temperature

Temperatures

The short-term permitted maximum temperature is 338° F. With increasing temperatures, the compressive strength of iglide® A200 plastic bushings decreases. Fig. 8.3 clarifies this connection. The temperatures prevailing in the plastic bushing system also have an influence on the bushing wear.

Temperature limits

| iglide® A200 | Application temperature |

|---|---|

| Minimum | - 40 °F |

| Max. long-term | + 176 °F |

| Max. short-term | + 338 °F |

| Additional axial securing | + 122 °F |

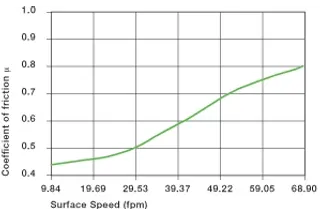

Figure 2.4: Coefficients of friction dependent on the surface speed, p = 108 psi

Friction and wear

The coefficient of friction alters like the wear resistance with increasing load. In iglide® A200 plastic bushings, the friction coefficient µ slightly rises with increasing load. Friction and wear also depend to a high degree on the reverse partner. The shaft can be a decisive factor for an ideal pairing of the bushing system. Thus extremely smooth shafts enhance not only the coefficient of friction, but also the bushing wear. The most suited are smoothed surfaces with an average surface finish of Ra = 16 to 24 rms.

| iglide® A200 | Dry | Grease | Oil | Water |

|---|---|---|---|---|

| Coefficients of friction µ | 0.10 - 0.40 | 0.09 | 0.04 | 0.04 |

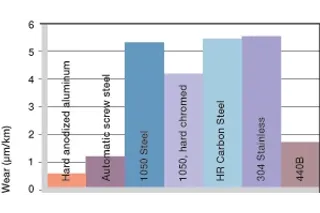

Fig. 2.7: Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

The diagrams display a summary of the results of tests with different shaft materials conducted with plastic bushing made of iglide® A200.

The combination "iglide® A200/hard-chromed shaft" clearly stands out. Up to a range of about 362 psi, the wear of this combination remains largely independent of load.

In pivoting applications below a load p = 290 psi, the wear of iglide® A200 plastic bushings is higher than in rotating applications with equal load. Here the HR carbon steel shaft is a positive exception with its much less coefficient of wear.

Please contact us in case the shaft material scheduled by you is not included in these figures.

Installation tolerances

iglide® A200 plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9).

After the installation in a housing bore with the tolerance H7, the inner diameter of the bushing automatically adjusts to the D11 tolerance.

| Diameter d1 [inches] | Shaft h9 [inches] | iglide® A200 D11 [inches] |

|---|---|---|

| Up to 0.019685 | 0 - 0.0009842 | +0.0007874 + 0.0031496 |

| > 0.1181 to 0.2362 | 0 - 0.0011811 | +0.0011811 + 0.0041339 |

| > 0.2362 to 0.3937 | 0 - 0.0014173 | +0.0015748 + 0.0051181 |

| > 0.3937 to 0.7087 | 0 - 0.0016929 | +0.0019685 + 0.0062992 |

| > 0.7087 to 1.1811 | 0 - 0.0020472 | +0.0025591 + 0.0076772 |

| > 1.1811 to 1.9685 | 0 - 0.0024409 | +0.0031496 + 0.0094488 |

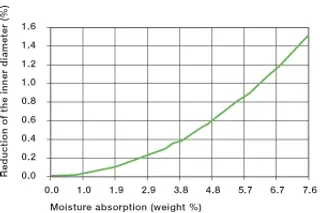

Figure 8.10: Influence of moisture absorption of iglide® A200 plastic bushings

Radioactive rays

iglide® A200 plastic bushings are radiation resistant up to a radioactive intensity of 2 x 104 Gy. Higher radiations affect the material and can lead to the loss of important mechanical properties.