Change Language :

Wear test for customers

Medium-load pivot test set-up in the dry-tech® laboratory.

The wear of three different pre-selected iglide® plain bearings was measured for a customer at an igus® test facility. It was necessary as a first step to find a material similar to that of the provided shaft.

**The wear test was carried out under the following parameters:**Plain bearing: iglide® L280, iglide® G300, iglide® P

counter partner (shaft material): Cf53 (1050) hard chrome plated

Movement type: pivoting

Swivel angle: 60°

Load: 2,176 psi

Speed: 0.0328 f/s

Lubrication: dry

Result:

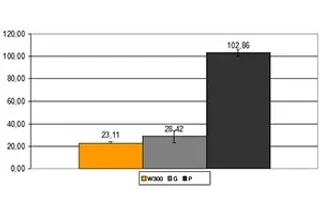

Wear rates (μm/km) of iglidur® W300, iglidur® G and iglidur® P on a hard chromed Cf53 shaft. Load: 15 MPa, speed 0.01 m/s, swivel angle 60°

The tests showed a result of an average wear rate of 23.11 µm/km for the iglidur® W300 bearings, of 28.42 µm/km for iglidur® G plain bearings and of 102.86 µm/km for the iglidur® P plain bearings respectively. With a wear rate of 23.11 μm/km, the iglidur® W300 plain bearings have the lowest wear in the final result.

Do you wish to test a custom application?

We will gladly test your specific application as well. Simply use the contact form!