Change Language :

Temperature-Wear testing

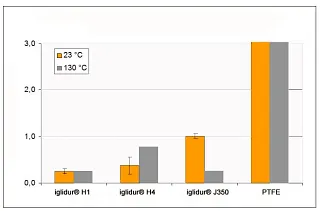

Polymer plain bearings have lower wear rate than PTFE plain bearings

Service life increases and costs are cut when plain bearings have reduced wear. A comparative test on behalf of a customer contrasts wear on an iglide® H1 plain bearing with the previously used PTFE solution and other iglide® materials. Testing was performed with the following parameters:

Travel distance: 25 miles

Load: 73 psi

Test temperature: 73 °F and 266 °F

Bearing types: iglide® H1, iglide® H4, iglide® J350, PTFE-bearings

Conclusion:

The wear characteristics of all tested iglide® materials are significantly better than those of the PTFE plain bearing. At 130 °C (266 °F), the wear rate of the PTFE plain bearing is 55.7 µm/km, and 0.3 µm/km for iglide® H1.

Do you wish to test a custom application?

We will gladly test your specific application as well. Simply use the contact form!