Change Language :

drylin® R - Technical information

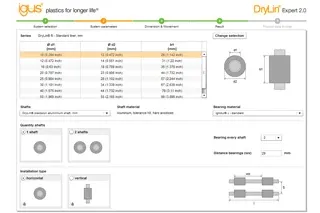

DryLin® Expert System

Use the Expert System to quickly find out which drylin® linear bearing will work in your application.

Calculate lifetime, clearance, and generate CAD files and RFQs using one simple program.

Materials table

| General features | Unit | iglide® J | iglide® T500 | iglide® J200 | Test method |

|---|---|---|---|---|---|

| Density | g/cm3 | 1.49 | 1.44 | 1.72 | |

| Color | Yellow | Black | Dark grey | ||

| Max. humidity absorption at 73°F/50% R. H. | Wt.-% | 0.3 | 0.1 | 0.2 | DIN 53495 |

| Max. water absorption | Wt.-% | 1.3 | 0.5 | 0.7 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.06 - 0.18 | 0.09 - 0.27 | 0.11 - 0.17 | |

| p x v value, max. (dry) | psi x fpm | 9,700 | 37,700 | 8,600 | |

| Mechanical properties | |||||

| Bending E-module | psi | 348000 | 1174500 | 406000 | DIN 53457 |

| Bending strength at 68°F | psi | 10585 | 24650 | 8410 | DIN 53452 |

| Compressive strength | psi | 8700 | 14500 | n.d. | |

| Recommended max. surface pressure (68°F) | psi | 5075 | 21750 | 3335 | |

| Shore D hardness | 74 | 85 | 70 | DIN 53505 | |

| Physical and thermal properties | |||||

| Upper long-term temperature | °F | 194 | 482 | 194 | |

| Upper short-term application temperature | °F | 248 | 599 | 248 | |

| Lower application temperature | °F | -58 | -148 | -58 | |

| Heat conductivity | [W/m x K] | 0.25 | 0.6 | 0.24 | ASTM C 177 |

| Coefficient of thermal expansion (at 73.4 °F) | [K-1 x 10-5] | 10 | 5 | 8 | DIN 53752 |

| Electrical properties | |||||

| Specific forward resistance | Ωcm | >1013 | < 105 | >108 | DIN IEC 93 |

| Surface resistance | Ω | >1012 | <103 | >108 |

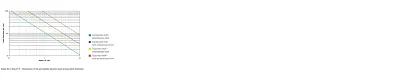

DryLin® R - Comparison of the permitted dynamic loads with same diameter

Dirt, dust, fibers

drylin® R is reliable despite the presence of dust or abrasive dirt particles

An important feature of all drylin® linear bearings is their tolerance of dirt. For most bearing systems, the use of wipers or seals is recommended for even low dirt accumulation. drylin® is not affected by dust, lint, or coarse dirt.

The patented design of the bearing using individual slide pads, connected by thin film sections, provides performance benefits for dirty environments..

Dirt, even when it becomes wet on the shaft, is wiped away by the individual glide pads and moved into the contact-free areas. The glide sections of the drylin® bearings then slide on the shaft that has been cleared of all contaminants.

Split linear bearings

The drylin® liner can be pushed easily onto the shaft

Applications that operate on the edge of technical feasibility or in extremely harsh environments are characterized by need to frequently replace linear bearings. In many cases, service life can be multiplied many times with drylin®. However, in extreme applications, even drylin® bearings may need to be replaced from time to time.

drylin® linear bearings can contribute to considerable cost reductions in such cases, since only the iglide® bearing liner has to be replaced. This often means a reduction of more than 90% in replacement part costs. iglide® liners can be replaced, while a ball-bearing cage can not.

Split adapters offer even greater cost savings. Shafts need no longer be removed from the housing. The two shells of the adapter can be opened very easily. The high-performance plastic bearing inside is split and can easily be pulled off the shaft. Clip a new bearing over the shaft, put the two adapter halves together and install.

Split adapters help reduce installation times to a minimum.