Robotic Arms & Parts for Industrial Automation

robolink® DP is a 4 or 5-axis robotic arm featuring self-lubricating, maintenance-free plastic joints. It can be designed with or without our integrated control system. Other features include an optimized bearing support for each axis to reduce backlash, a payload up to 30N, cycle times from 6 seconds, and a reach up to 790mm. We offer robolink® DP in a small or large size as well as motor and drive encoders upon request. We can also customize a robotic arm using the components below to meet your specific application requirements.

If you're looking for even lower cost solutions that do not require as high speed and/or precision, consider robolink® DCI or DC, our "Legacy Series" robotic arms. It features the same self-lubricating plastic joints as robolink® DP and can be purchased as a complete robot or customized using our robolink® designer tool.

Applications/Industries

Applications/Industries

- Material Handling & Assembly

- Welding, Painting & Drilling

- Automanufacturing

- Pick and place

Download the robolink® DP Technical Data Sheet

Shop robolink® DP 4 or 5 DoF robotic arms

- Payload up to 30N, Cycle times > 6s, Reach up to 790mm

- Available as DPI version with integrated control system

- Motor and drive encoders available upon request

- Optimized bearing support for each axis to backlash

Shop robolink® DP

Looking to Speak with a Product Specialist?

Contact a product specialist now

Shop robotic components

drygear® strain wave gear

- Compact design

- Available transmission: 28:1

- Standard motor option: Stepper motor NEMA11 or 17

- INI-Kit for zero position optionally adaptable

- Adaptor disc for flanging on grippers available

Browse drygear® strain wave gear

Robotic joints

- Slewing ring bearing (iglide® PRT) with plastic housing

- The main component is a worm gear

- Cables can be guided through the center hole

- The joints can be ordered with or without motor

Browse robotic joints

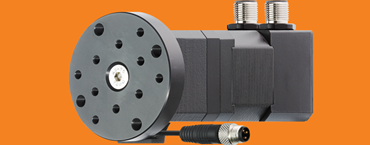

Rotary Axis with Motor

- robolink® D robotic joint, symmetrical - with two PRT slewing ring bearings with direct drive

- The main component is a worm gear, & cables can be guided through the center hole

- Self-locking drive

- Application horizontal on base plate

Shop Rotary Axis with Motor

Strain wave gears with motors

- Installation size: 17 with NEMA17/flange dimension 42 mm

- Optional motor connections: wire, connector, encoder and brake

Shop strain wave gears with motors

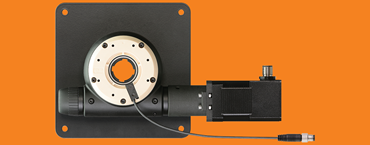

Gearbox with Cantilever Actuator

- The linear gearbox enables different strokes in the application.

- Rack and pinion elements included.

- Configurable in different lengths for sliding applications.

Shop Gearbox with Cantilever Actuator

Gearbox Joint with Motor

- Installation size: NEMA17/flange installation size 42mm

- Holding torque: 0.5Nm

- Nominal current: 1.80A

- Motor connection: Stranded wire

Shop Gearbox Joint with Motor

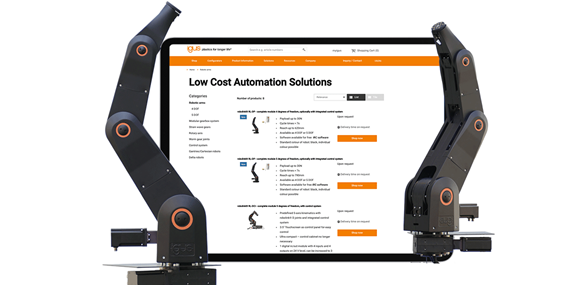

Browse our legacy robolink® arms and more!

robolink® DCI

- 3.5" Touchscreen as easy control panel

- Ultra compact – control cabinet no longer necessary

- 1 digital in/out module with 4 inputs/outputs on 24 V level, up to 3 modules

Shop robolink® DCI

robolink® DC

- 4 or 5 degrees of freedom

- Motor encoder

- INI kit

- Reach: 600 or 750 mm

- Payload: 1,000 or 3,000g

Shop robolink® DC

Browse all Low Cost Automation

- Gantries & cartesian robots

- Delta pick and place robots

- Linear actuators

- Electric linear actuators with motors

- Multi-axis cable carriers for robots

Browse Low Cost Automation