iglide® X6 - material data

Materials table

| General features | Unit | iglide® X6 | Test method |

| Density | g/cm³ | 1.53 | |

| Color | Blue grey | ||

| Max. moisture absorption at 73°F/50% r.h. | Wt.-% | 0.1 | DIN 53495 |

| Max. moisture absorption | Wt.-% | 0.5 | |

| Coefficient of friction, dynamic against steel | µ | 0.09 - 0.25 | |

| P x v value, max. (dry) | psi x fpm | 38,350 | |

|

Mechanical properties |

|||

| Modulus of elasticity | psi | 2,320,600 | DIN 53457 |

| Tensile strength at 68° F | psi | 46,060 | DIN 53452 |

| Compressive strength | psi | 27,557 | |

| Permissible static surface pressure (68°F) | psi | 21,755 | |

| Shore D hardness | 89 | DIN 53505 | |

|

Physical and thermal properties |

|||

| Max. long-term application temperature | °F | 482 | |

| Max. short-term application temperature | °F | 599 | |

| Min. application temperature | °F | -148 | |

| Thermal conductivity | W/m x K | 0.55 | ASTM C 177 |

| Coefficient of thermal expansion (at 23° C) | [K-1 x 10-5] | 1 | DIN 53752 |

|

Electrical properties |

|||

| Specific volume resistance | Ωcm | < 105 | DIN IEC 93 |

| Surface resistance | Ω | < 105 | DIN 53482 |

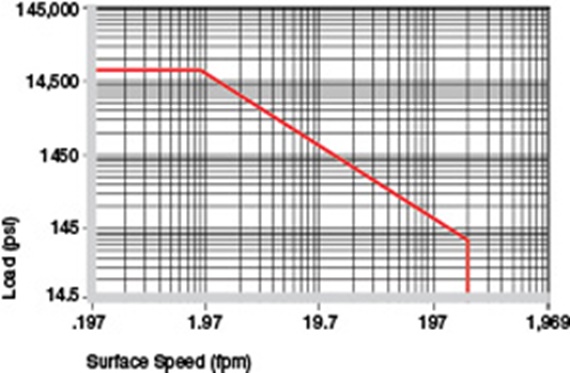

Permissible surface speeds

Due to its high temperature resistance and good thermal conductivity, iglide® X6 plastic plain bearings are also suitable for high speed applications. At the speeds given, friction can cause a temperature increase to the maximum permissible levels. In practice, this temperature is rarely reached.| fpm | Rotary | Oscillating | Linear |

| Continuous | 295 | 216 | 984 |

| Short term | 689 | 492 | 1969 |

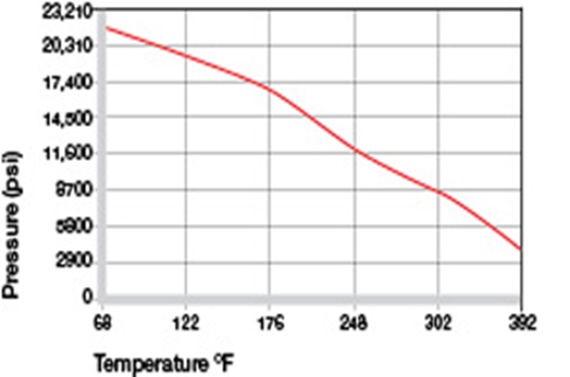

Temperatures

The surrounding temperatures noticeably influence the wear performance of plastic plain bearings. The temperature resistance of iglide® X6 is among the highest in the iglide® range. In many tests it has shown a six times higher wear performance compared to the established high-temperature bearing iglide® T500. Another advantage to iglide® X6 is that axial fastening is only necessary at temperatures above 320°F.| iglide® X6 | Application temperature |

| Minimum | –148°F |

| Max., long-term | +482 °F |

| Max., short-term | +599 °F |

| Add. securing is required from | +329 °F |

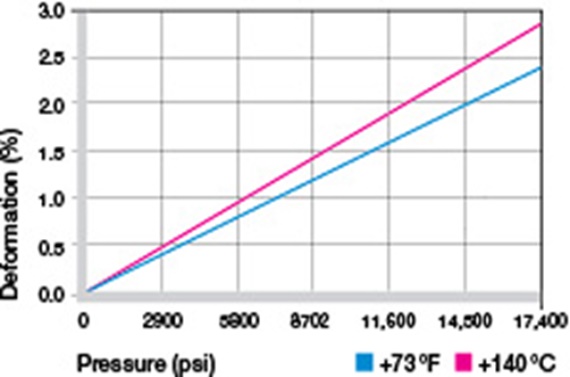

Compressive strength

With increasing temperatures, the compressive strength of iglide® X6 plain bearings decreases. The graph on the left shows the elastic deformation of iglide® X6 with radial loads. At the recommended maximum surface pressure of 290 psi, the deformation is less than 2%.

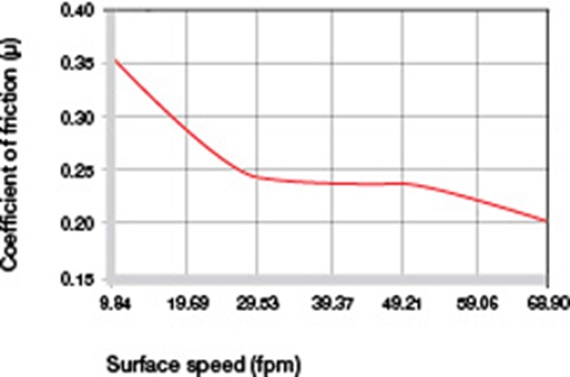

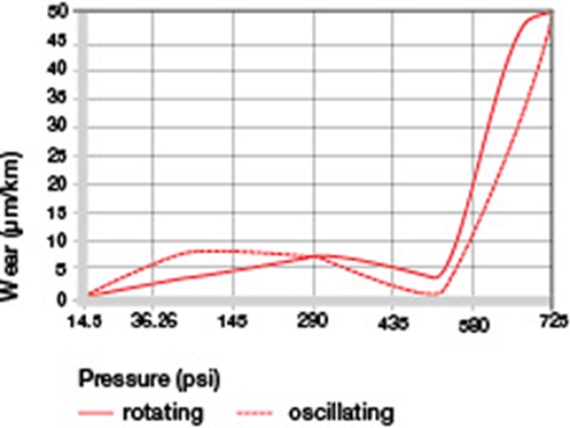

Friction and wear

Similar to wear resistance, the coefficient of friction μ also changes with the load. The coefficient of friction of iglide® X6 declines with higher pressure and is practically constant for pressure above 4,350 psi. A higher speed also results in a lower coefficient of friction.

Shaft materials

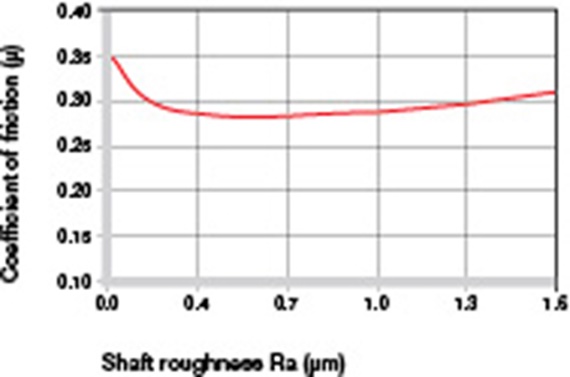

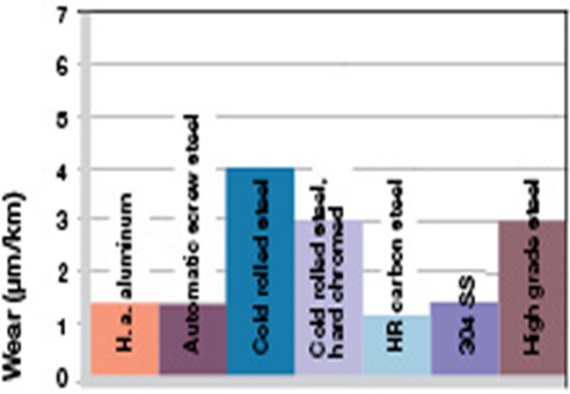

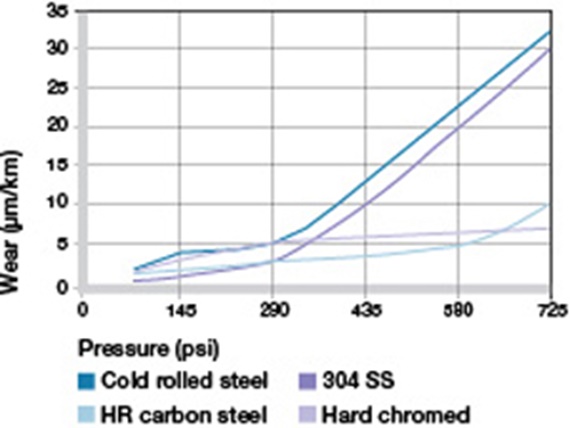

The friction and wear are also dependent, to a large degree, on the shaft material. Shafts that are too smooth increase both the coefficient of friction and the wear of the plain bearing. The best shaft for iglide® X6 has a ground surface with an average roughness of Ra = 0.4 - 0.7 μm (figure 06).Figures 06 and 07 show the results of testing different shaft materials with plain bearings made from iglide® X6.

In Graph 07, you can that iglide® X6 can be combined with various shaft materials.

Coefficients of friction for iglide® X6 against steel (Ra = 1 µm, 50 HRC):

| iglide® X6 | Dry | Grease | Oil | Water |

| Coefficients of friction μ | 0.09–0.21 | 0.09 | 0.04 | 0.04 |

Chemical resistance of iglide® X6 at room temperature [+68 °F]

| Medium | Resistance at 68°F |

| Alcohol | + |

| Hydrocarbons | + |

| Grease, oils without additives | + |

| Fuels | + |

| Diluted acids | + |

| Strong acids | + |

| Diluted alkalines | + |

| Strong alkalines | + |

Electrical properties

| Specific volume resistance | < 105 Ωcm |

| Surface resistance | < 105 Ω |

Chemical resistance

iglide® X6 bearings have almost universal chemical resistance. They are only affected only by concentrated nitric acid and sulfuric acid. Due to its low moisture absorption, the material can be used in humid environments without problems. iglide® X6 is resistant to most typical detergents used in the food and packaging industries.Radiation resistance

Plastic plain bearings made from iglide® X6 are resistant to radiation up to an intensity of 2 x 105 Gy.y of 2 x 105 GyUV Resistance

Partially resistant against UV rays.Vacuum

In a vacuum environment, iglide® X6 plain bearings can be used virtually without restrictions. Outgassing takes place to a very limited extent.

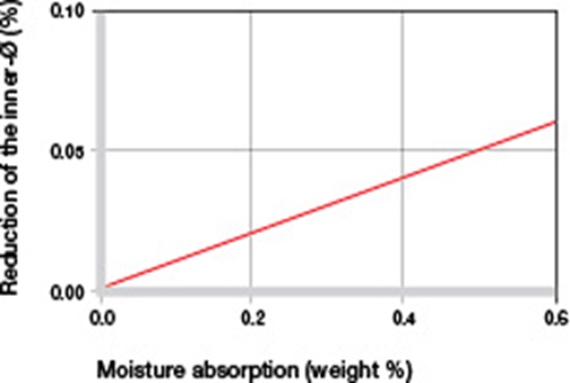

Moisture absorption

The moisture absorption of iglide® X6 plastic plain bearings in relation to the size of the inner diameter (left).| Maximum moisture absorption | |

|---|---|

| At +73°F/50% relative humidity | 0.1 weight-% |

| Max. moisture absorption | 0.5 weight-% |