Change Language :

iglide® Plastic Bushings - Tolerances

Tolerances and Measuring System

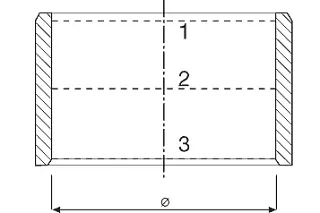

Picture 1.20: Measuring of the inner diameter of a pressfit iglide® bushing

The installation dimensions and tolerances of iglide® plastic bushings are dependent on material and wall thickness. For each plastic bushing material, moisture and thermal expansion are critical. plastic bushings with low moisture absorption can be obstructed when there is a minimal amount of tolerance. For wall thickness, the rule is: the thicker the bushing wall is, the larger the tolerances must be.

For this reason, different tolerance classes exist for iglide® plastic bushings:

With these tolerances, iglide® plastic bushings can operate in the permissible temperature range and up to 70% humid conditions according to the installation recommendations. Should higher moisture levels be present in the air, or the bushing operate under water, our technical expertise is freely available to help you.

Testing Methods

iglide® plastic bushings are pressfit for bores set to our recommendations. Pressfitting fixes a bushing into a housing and forms its inner diameter.

igus® uses a pin-gauge test, also called a “go / no-go” test, to make sure our bearings are within specifications and will work properly once in operation.

- The 'Go-Side' of the gauge, press-fit into the bore, must pass easily through the bearing.

- With the 3 point probe, the inner diameter of the bearing after pressfit must lie within the prescribed tolerance on the measurement plane (see Fig. 1.23 below).

Troubleshooting

Figure 1.23: The position of the measuring levels (1, 2, 3 = measuring lines)

Despite careful manufacturing and bearing assembly, variations and questions regarding the recommended installation dimensions and tolerances can arise.

For this reason, we have listed the most frequent causes for variations. With this troubleshooting guide, in many cases the causes for variations can be quickly found.

- Bearing is oversized before pressfit – check dimensions only after pressfit.

- Removal of material when pressed into housing – add chamfer to housing bore, check bore size.

- Bearing is over-/under-sized after pressfit – check housing bore dimension, check housing bore material. Softer bore materials (plastic, aluminum) can expand upon pressfit.

- Operating clearances are too large/small – check ID of bearing after press, housing bore, shaft diameter.

- Bearing noise/squeak – check shaft surface finish / possibly roughen shaft.

- Bearing wears, material deposits on shaft – operating clearance may be too small / increase clearance.

- Chattering noise – operating clearance too large, excessive speed / reduce speed and operating clearance.

- Shaft wear – shaft material too soft / change shaft material or hardness, switch to alternative iglide material.

- Bearing seizes on shaft – operating clearances too small, temperature or moisture may be causing material expansion.

- Loss of pressfit – bearings overheated / axial secure bearing into housing or select alternative material grade.

Additional Technical Information

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert