Change Language :

iglide® Plastic Bushings - Temperature

Temperatures

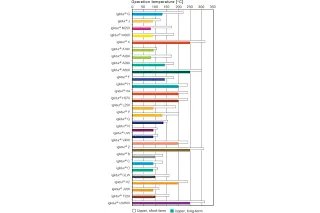

Figure 1.10: Comparison of the long-term and short-term upper application temperatures

Plastic bushings are often underestimated, especially at higher temperatures. It's difficult to believe that they can be used in temperatures over 572°F. Continuous-use temperature is the highest temperature the plastic bushing can withstand for a prolonged period of time without a reduction in the tensile strength of the material.

Please note, these standardized test results have limited application, since bearings are almost always subjected to a load. The wear limits of the material at certain application temperatures is more instructive.

Table 1.5: Lower application temperatures

The minimum application temperature is the temperature below which the material becomes so rigid and hard that it is too brittle for standard applications. The maximum continuous application temperature is the temperature which the material can endure without its properties changing considerably.

The maximum short-term application temperature is the temperature above which the material becomes so soft, that it can only withstand low external loads. 'Short-term' is defined as a time period of a few minutes. If the plastic bushings are moved axially or axial forces occur, there is more opportunity for the bushing to lose its pressfit. In these cases, axial securing of the bushing is required in addition.

Column 3 shows the maximum ambient temperatures to which the plastic bushings can be exposed in the a short-term. If these temperatures are reached, the bushings may not be additionally loaded. In fact, a relaxation of the bushings can occur at these temperatures, even without an additional load. For this reason, it's necessary to ensure that the bushing can not slide out of the bore. This is achieved by changing the bore construction or by additionally securing the bushing.

Column 4 shows the maximum ambient temperature the plastic bushings can tolerate for a short period of time. If these temperatures are acting on the bushings, they should not be additionally stressed. At these temperatures, relaxation of the bushings inside the housing can occur, even without any additional load. Attention should be given to ensuring the plastic bushings are prevented from slipping out of the bore either by changing the bore construction or by additionally securing the bushing.

| Material | Lower application temperatures [°F] | Fastening is to be provided from [° F] | Upper short-term ambient temperature [° F] |

|---|---|---|---|

| iglide® G (formerly G300) | -40 | 212 | 428 |

| iglide® J | -72.4 | 140 | 284 |

| iglide® M250 | -40 | 140 | 392 |

| iglide® W300 (formerly L280) | -40 | 140 | 392 |

| iglide® X (formerly T500) | -234 | 275 | 599 |

| iglide® A180 | -58 | 140 | 230 |

| iglide® A200 | -40 | 122 | 392 |

| iglide® A290 | -40 | 230 | 446 |

| iglide® A500 | -148 | 266 | 599 |

| iglide® F | -40 | 221 | 446 |

| iglide® H | -40 | 248 | 500 |

| iglide® H4 | -40 | 230 | 500 |

| iglide® H370 | -40 | 212 | 500 |

| iglide® L250 | -40 | 131 | 392 |

| iglide® P | -40 | 194 | 392 |

| iglide® Q | -40 | 122 | 392 |

| iglide® R | -58 | 122 | 284 |

| iglide® UW | -58 | 176 | 284 |

| iglide® V400 | -58 | 212 | 482 |

| iglide® Z | -148 | 293 | 590 |

| iglide® B | -40 | 122 | 266 |

| iglide® C | -40 | 104 | 302 |

| iglide® D | -58 | 122 | 284 |

| iglide® GLW | -40 | 176 | 392 |

| iglide® H2 | -40 | 122 | 500 |

| iglide® J200 | -58 | 140 | 284 |

| iglide® T220 | -40 | 122 | 338 |

| iglide® UW500 | -148 | 302 | 599 |

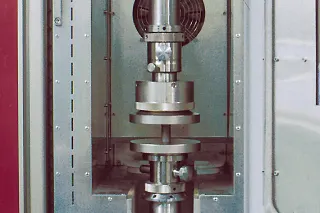

Picture 1.11: Material tests are possible up to 482° F.

Temperature and load

The compressive strength of plastic bushings decreases with increasing temperature. At the same time, the materials act very differently from one another, for instance iglide® T500 permits loads of 10,150 psi even at 392°F temperatures.

Coefficient of thermal expansion

The thermal expansion of plastics is approximately 10 to 20 times higher in comparison to metals. In contrast to metals, it also does not act linearly on plastics. The iglide® bushing's coefficient of thermal expansion is a significant reason for the required play in the bearing. Seizing of the bearing to the shaft does not occur at high temperatures. The coefficients of thermal expansion of iglide® plastic bushings were tested for significant temperature ranges and the results are given in the individual materials tables in each relevant product section.

Additional Technical Information

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert