Components from a good family

fabmaker relies on proven linear guide components for 3D printers

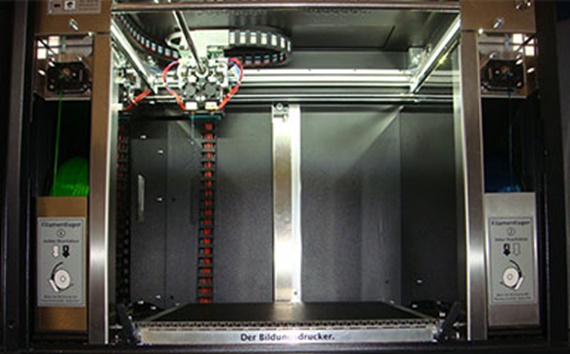

Technology-oriented start-up businesses are more daring than others in deploying emerging technologies in new, marketable products. This is also true of fabmaker GmbH, Braunschweig, who have developed a 3D printer for educational purposes. When choosing the functional elements and components for their "educational printer", the staff headed by managing director Dean Ćirić rely on industry-proven products and services as demonstrated by the collaboration between fabmaker and igus®.In principle, 3D printing is the continuation of stereolithography, a process developed 30 years ago, that was rebranded as "Rapid Prototyping" by resourceful software developers in the mid-1990s. But in the meantime 3D printers provide much more than just prototypes used by developers to exchange views on the functions, the design and the haptics of their creations. Chinese companies now use 3D printing to produce large-scale construction segments that can be put together to form detached houses just like Lego blocks. A roof over your head for around 7,000 euros; but only in China, however...

"There was a lot of hype about 3D printing around three years ago," explains Daniel Kerlin, who is responsible for marketing and sales at fabmaker. "That was the point at which we said that this technology is ready for the market. All that needs to be done is to introduce it to people. Pupils at primary and secondary schools, apprentices in businesses, students and colleges and universities should be able to learn about all the things that are possible with this technology. So it became our objective to develop a 3D printer with two printer heads that is easy to operate and that works safely and reliably to produce professional results thanks to its technical properties and software. And in order to be able to process filaments either in two colours or of two different materials, our 3D printer had to have two printer heads. “

The aim of the development work was the "educational printer"

This not only defined the business operations and the unique selling points of the new product but also the stated target market of the young enterprise: education and training. It is a huge market but one that has been left unnoticed to a great extent. Firstly, the education sector lacks a lobby. Secondly, most companies address industrial applications with their newly developed or refined products, which as a rule boils down to predatory competition

Before the "educational printer" was launched, Daniel Kerlin and Stefan Silder, who were responsible for technical development at fabmaker, had a very close look at 3D printers that were on the market at that time. In Kerlin's words, there were "in some cases already remarkable differences" that had shown them which details they needed to focus on in their own design.

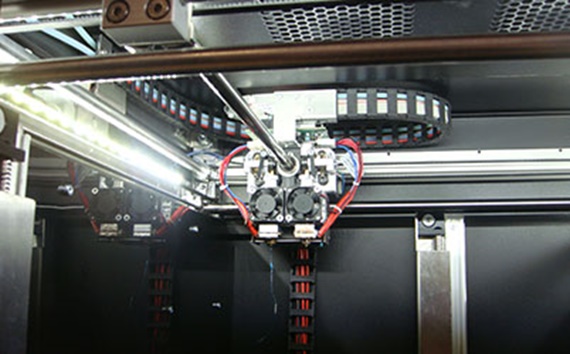

One of the main criteria was precise, vibration-free positioning of the two printer heads holding the jets through which the filaments heated to 250 °C flow to make it possible to create the contours desired using molten layers. While the specification was defined as "not as precise as possible but as precise as necessary", what this actually meant is demonstrated by the positioning precision of the jets achieved: 0.0125 millimetres.

One of the main criteria was precise, vibration-free positioning of the two printer heads holding the jets through which the filaments heated to 250 °C flow to make it possible to create the contours desired using molten layers. While the specification was defined as "not as precise as possible but as precise as necessary", what this actually meant is demonstrated by the positioning precision of the jets achieved: 0.0125 millimetres.

The prerequisite for this is, of course, an extremely precise linear guide along which the printer heads are moved in x, y and z directions. This guide should not only be precise but also lubrication-free and, to the greatest extent, maintenance-free. "Lubrication-free was a must" explains Stefan Silder. "It would be fatal if lubricants such as oil or grease were to escape at temperatures in excess of two hundred degrees and contaminate the object being printed or the working chamber. And we aim to make the printer maintenance free as it is essentially a teaching aid that needs to be available at all times and has to work reliably for many years. Furthermore, the people being introduced to 3D printing technology have very different levels of previous technical experience. This means that the printer must very forgiving of operating errors. "Last but not least, such a linear guide has to be reasonably priced."

High-performance plastics make a maintenance-free product possible.

On the basis of these specifications, Daniel Kerlin and Stefan Silder searched the market for a linear guide of this kind, compared different products by various providers, tested them, rejected them and finally found what they were looking for at igus® in Cologne. This was not without justification because they did after all need energy chains for their 3D printers. But more on this later.Maik Röttger, at that time starting out as a Technical Sales Consultant at the igus® office Hannover, recommended the Braunschweig-based young entrepreneurs deploy a pre-assembled linear guide from the drylin® W modular system. He pointed out another argument for a lubrication-free application: "lubricants attract dirt and dust. These are things that nobody needs in the working chamber for a 3D printer or, for that matter, in a cleanroom where drylin® W series linear guides are similarly deployed in many different applications. “

A full modular system for the widest range of requirements

Here, liners made of various lubrication-free iglidur® high performance polymers ensure that drylin® W guides move "silently" in comparison to carriages on ball-bearing guides. They can be easily clipped into the bearing housing that is available in aluminium, stainless steel or zinc-die casting options. As an option, the bearing clearance can be set to customer specifications. Available as single or double rail systems, the drylin® W linear guides have a modular design. Its profile rails are made of hard anodised aluminium that stands for the best possible friction properties, low wear and light-weight design. Alternatively, the guides are also available in stainless steel or (the ultralight option) made from carbon and GFP. And there are square rails with floating bearing function for 90 degree installation. All in all, easy to mount.

But then there was still the question of which energy chains were to be used in fabmaker's educational printers. "When it comes to energy chains, there is just no way around igus®" says Stefan Silder emphatically. "As we all know, this Cologne-based company has been developing high-performance plastics for more than forty years now and has the most extensive portfolio of plastic chains the world over. Considering this variety, we first of all needed in-depth technical consultation as to which chain type would be best to meet our needs. “

Frank Klingemann, Technical Sales Consultant for e-chain systems® based in Salzgitter, was there to provide prompt advice. He remembers: "fabmaker need two e-chains® for their 3D printer. One running upright in the vertical z axis that securely guides the control and supply lines for the print bed and an unsupported one for the control and supply lines for the print head in the horizontal x/y axis. The chains should, of course, be maintenance-free and additionally their bend radius should be as small as possible, so that they do not extend too far into the working chamber. Furthermore, the energy chain running horizontally should not sag. “

On the basis of these requirements, a light and cost-effective E2 micro series chain lent itself for both applications. But after a few tests, it transpired that this chain sagged a little at the print heads. Frank Klingemann suggested a more stable chain type: an E2.1 micro series chain. And he recommended guiding the chain in the reverse direction to the print heads. He was spot on with this assessment as was demonstrated by the subsequent tests.

This chain type is suitable for unsupported applications of up to 0.75 metres. It is robust, runs quietly and offers inner widths of up to 50 millimetres with its smooth contours ensuring as little wear as possible on the cables.

Daniel Kerlin, quite the perfectionist, sees scope for optimisation, nevertheless and at the same time expresses praise for the good collaboration with the two consultants from igus®: "Although we are not constantly in contact with each other, we can get in touch with igus® whenever we have any questions. And Maik Röttger or Frank Klingemann will also come to us in the technology park whenever we want to test a different energy chain or when we would like to discuss technical details in a little more detail. “

On the basis of these requirements, a light and cost-effective E2 micro series chain lent itself for both applications. But after a few tests, it transpired that this chain sagged a little at the print heads. Frank Klingemann suggested a more stable chain type: an E2.1 micro series chain. And he recommended guiding the chain in the reverse direction to the print heads. He was spot on with this assessment as was demonstrated by the subsequent tests.

This chain type is suitable for unsupported applications of up to 0.75 metres. It is robust, runs quietly and offers inner widths of up to 50 millimetres with its smooth contours ensuring as little wear as possible on the cables.

Daniel Kerlin, quite the perfectionist, sees scope for optimisation, nevertheless and at the same time expresses praise for the good collaboration with the two consultants from igus®: "Although we are not constantly in contact with each other, we can get in touch with igus® whenever we have any questions. And Maik Röttger or Frank Klingemann will also come to us in the technology park whenever we want to test a different energy chain or when we would like to discuss technical details in a little more detail. “

And the customers of this start-up company? "They are obviously satisfied with our 3D printers", says Daniel Kerlin in conclusion, "at least there have been no cases where a device has been returned to us because of a technical defect." “

Stefan Silder responds with a telling smile to the question as to whether fabmaker was already working on a 3D printer with even more print heads and which energy chains and linear guides might then be needed: "This is currently not on the cards but should we go down this path we are certain to talk to igus® first of all". “

Stefan Silder responds with a telling smile to the question as to whether fabmaker was already working on a 3D printer with even more print heads and which energy chains and linear guides might then be needed: "This is currently not on the cards but should we go down this path we are certain to talk to igus® first of all". “