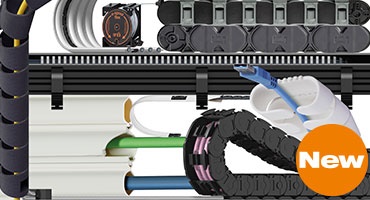

autoglide 5 - energy and data transmission installed in one hour

Save 88% assembly time with cost-effective energy chain for intralogistics and crane systems

The igus system autoglide 5 transmits energy, data, liquids and air safely and practically maintenance-free in a system at a cost-effective price.Technical data:

| Travel | Speed | Noise during operation | |||

|---|---|---|---|---|---|

| 80m | 4 m/s | 63dB(A) at 2m/s |

Tech up

- Energy, data, air and liquids in ONE system

- Often saves two or more other systems for transmitting data

- 4m/s speed

- 80m travel

- Quiet operation: 63db(A) at 2m/s

- 50% hall floor remains free, no guide trough needed

Cost down

- Assembly times 88% shorter than those for a conventional standard solution with guide troughs

- From €49/metre, ready for installation incl. e-chain 2400.07AG.075.0, steel cable guide, harnessed bus cable and 5 single cores of 6mm each2

- Available as a harnessed system with cables, hoses and connectors

- Less maintenance and cleaning requirements

Proof

- Tested in the igus laboratory and also by our customer, Company Beewen GmbH, installed

- Suitable for other industries and applications: storage and retrieval units, indoor cranes, port operators, sports facilities, theatres, machine tools, linear robots

Sustainability

- Energy consumption for autoglide 5 manufacture is 64% lower than that of an energy chain with aluminium trough on a 50m travel

- To recycle integrated energy chain through the igus chainge programme free of charge

- More on the igus contribution to Plastic2Oil

Additional components

Dampening elements

Reduces rolling noise and makes operation smoother

- Rolling noise reduced by 3dB(A) at 1m/s

- Quieter operation

- Simply insert into the track holder

- Time-saving retrofit

Fixed end bridge

Reduce cable length and save costs

- Centre infeed/reverse energy supply possible

- Shorter cable lengths

- Saves cable length

Product range:

Complete solution

[Travel: 10 - 60m]

1 complete set consists of:+ 2400.07AG5 energy chain

+ AG5 and AG individual parts

+ separators every 2nd link, pre-assembled

+ track holder for AG

+ upper run guide

+ mounting brackets for moving end

+ steel wire cable

+ cable tensioning unit

+ fixed end module

+ installation/mounting instructions

To the shop

Two-part energy chain

Four-part energy chain

Roller energy chain

*Available from Spring 2021

**Available from stock

*** Large bend radii upon request

| Part No. | Inner height | Inner width | Bend radius*** | |

|---|---|---|---|---|

| 2400.05AG5* | 25 mm | 57 mm | 075/100/125/150mm |  Submit an enquiry now Submit an enquiry now |

| 2600.07AG5* | 35 mm | 75 mm | 075mm |  Submit an enquiry now Submit an enquiry now |

| 2600.10AG5* | 35 mm | 100 mm | 075mm |  Submit an enquiry now Submit an enquiry now |

Four-part energy chain

| Part No. | Inner height | Inner width | Bend radius*** | |

|---|---|---|---|---|

| E4.32.10AG5* | 32 mm | 100 mm | 100/125/150/175/200mm |  Submit an enquiry now Submit an enquiry now |

| E4.32.112AG5* | 32 mm | 112 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| E4.32.12AG5* | 32 mm | 125 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| E4.32.15AG5* | 32 mm | 150 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| E4.32.17AG5* | 32 mm | 167 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| E4.32.20AG5* | 32 mm | 200 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| E4.32.262AG5* | 32 mm | 262 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| E4.42.10AG5* | 42 mm | 100 mm | 125mm |  Submit an enquiry now Submit an enquiry now |

| E4.42.112AG5* | 42 mm | 112 mm | 125mm |  Submit an enquiry now Submit an enquiry now |

| E4.42.12AG5* | 42 mm | 125 mm | 125mm |  Submit an enquiry now Submit an enquiry now |

| E4.42.15AG5* | 42 mm | 150 mm | 125mm |  Submit an enquiry now Submit an enquiry now |

| E4.42.17AG5* | 42 mm | 167 mm | 125mm |  Submit an enquiry now Submit an enquiry now |

| E4.42.20AG5* | 42 mm | 200 mm | 125mm |  Submit an enquiry now Submit an enquiry now |

| E4.42.262AG5* | 42 mm | 262 mm | 125mm |  Submit an enquiry now Submit an enquiry now |

Roller energy chain

| Part No. | Inner height | Inner width | Bend radius*** | |

|---|---|---|---|---|

| P4.32.10AG5* | 32 mm | 100 mm | 150/200mm |  Submit an enquiry now Submit an enquiry now |

| P4.32.10AG5* | 32 mm | 100 mm | 150mm |  Submit an enquiry now Submit an enquiry now |

| P4.32.112AG5* | 32 mm | 112 mm | 150mm |  Submit an enquiry now Submit an enquiry now |

| P4.32.12AG5* | 32 mm | 125 mm | 150mm |  Submit an enquiry now Submit an enquiry now |

| P4.32.15AG5* | 32 mm | 150 mm | 150mm |  Submit an enquiry now Submit an enquiry now |

| P4.32.17AG5* | 32 mm | 167 mm | 150mm |  Submit an enquiry now Submit an enquiry now |

| P4.32.20AG5* | 32 mm | 200 mm | 150mm |  Submit an enquiry now Submit an enquiry now |

| P4.32.262AG5* | 32 mm | 262 mm | 150mm |  Submit an enquiry now Submit an enquiry now |

| P4.42.10AG5* | 42 mm | 100 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| P4.42.112AG5* | 42 mm | 112 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| P4.42.12AG5* | 42 mm | 125 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| P4.42.15AG5* | 42 mm | 150 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| P4.42.17AG5* | 42 mm | 167 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| P4.42.20AG5* | 42 mm | 200 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

| P4.42.262AG5* | 42 mm | 262 mm | 100mm |  Submit an enquiry now Submit an enquiry now |

*Available from Spring 2021

**Available from stock

*** Large bend radii upon request

White paper: Energy chain with steel-rope guide as an alternative to a busbar?

Up to now, many users have been relying on busbars to supply power to indoor and outdoor cranes, electric trains and storage and retrieval units. A similar price to that of a busbar but with advantages in regard to installation, modularity and maintenance. autoglide 5 combines the best of both worlds. Read more in the white paper "Energy chain with steel-rope guide as an alternative to a busbar?"Download white paper now

Interactive Model Available

Explore our innovative and interactive 3d model of this product. Experience different design elements and visualize concepts with unparalleled precision.

Experience the 3d Model

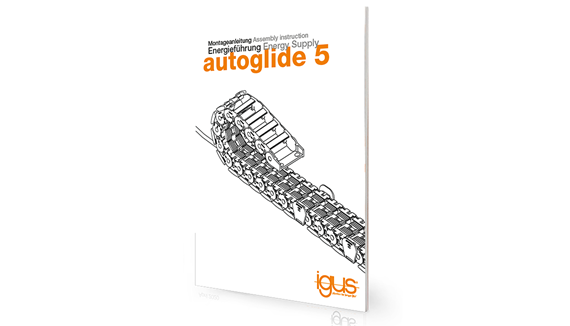

User problem:

Up to now, many have been relying on busbar systems for power and data transmission in tight, compact spaces and for fast lane movements, for example in storage and retrieval units. These are very simple in construction and very cost-effective. Their major disadvantage is that they are expensive to maintain, can only be used for power transmission as standard and must be cleaned regularly to avoid contact faults. Furthermore, they can ususally only transmit energy.Your advantages of using autoglide 5:

- Can easily be installed in the aisle on a rope or a profile

- Cost-effective price

- 88% shorter assembly time compared to aluminium troughs

- Long-lasting, maintenance-free and easy to clean

- Energy, data, air and liquids in ONE system

- 4m/s speed

- 80m travel

- Quiet operation: 63db(A) at 2m/s

- Hall floor remains free, no guide trough needed

- Available as harnessed system with cables, hoses and connectors

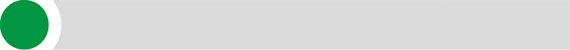

How does it work?

The e-chain can travel safely on the rope. The underside of the chain links has a guide element in the middle, so that the energy chain can rest safely on the rope. autoglide elements ensure wear-resistant and precise rolling of the upper run of the chain.

Installation instructions

The illustrated assembly aid enables you to assemble the autoglide 5 quickly and professionally.Download installation instructions for the autoglide 5 now

autoglide 5 for many industries and applications

The autoglide 5 system is not only of interest for storage and retrieval units, mini loads or other applications in material handling. Together with you, we develop concepts and prototypes that can be efficiently realised with the modular design of autoglide 5, the wide range of igus energy chains and cables as well as our experience. What parameters are essential for you? What speed, filling or travel is there in your application? Ask us and together we will develop a solution for your application that lowers costs and improves technology.Request autoglide 5 now

Questions and answers

Which chain type serves as the basis for the new autoglide 5? The basis is the model 2400 with 77mm width and 75mm bend radius. Other widths and radii are of course also possible.

What is the service life of the autoglide 5? As with all e-chains, we are aiming for the 10 million cycles or 10,000km. The tests for a guaranteed statement are still running in our laboratory.

What is the service life of the autoglide 5? As with all e-chains, we are aiming for the 10 million cycles or 10,000km. The tests for a guaranteed statement are still running in our laboratory.

Can I replace the crossbars if they wear out? Yes, because the special crossbars can simply be opened. Should they ever wear out, they can be easily replaced.

Can I also use a plastic rope? We are currently testing the use of a plastic rope.

Can I also use a plastic rope? We are currently testing the use of a plastic rope.

More autoglide series

Special solutions for long travels without guide troughs

Overview of e-chain news 2020

Discover here more e-chain news 2020

News product catalogue 2020

All the information you need about our new products and additions to the product range in the free catalogue.Download the catalogue now

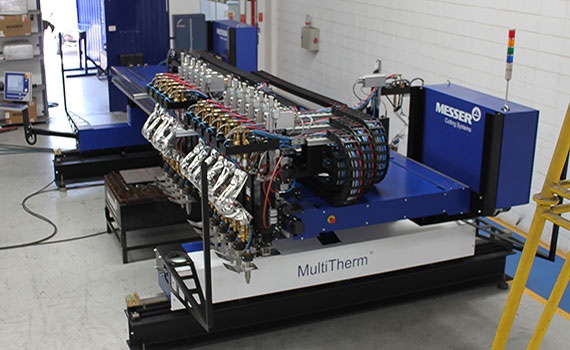

Application example with autoglide

Cutting machines

Here, e-chains from the 3500 series with bend radii of 150mm and 250mm were used. An autoglide system ensures that the chain glides straight over each other. The special comb-like crossbars enable the chain to basically guide itself, which means there is no need for an additional guide trough. In addition, one of the special technical and economic advantages of igus products is the cost saving

Find out more

More energy chain applications

Here you will find an overview of further successful examples of our customers.