How does 3D printing work?

Additive manufacturing (commonly referred to as 3D printing) is a manufacturing method where material is added layer by layer to create a solid object. There are different types of 3D-printing, but this is the basic principle of every process. First, you must create a CAD file, which is a 3D digital model of the object that will serve as the basis for production. Then, software slices the CAD file into layers, and it’s sent to the printer where the process begins.

Benefits:

- Production time typically between 2-3 days

- Reduced development and production costs

- No tools required to produce three-dimensional components. A CAD file serves as the basis for production

- Simple and cost-effective changes to the component are possible

- Reduced risk of defects in high-volume production

- More component design freedom

- Significant reduction of material waste during production compared to ablative processes

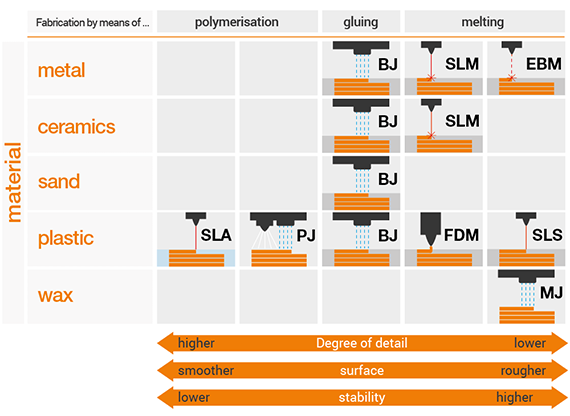

Overview of various 3D printing methods

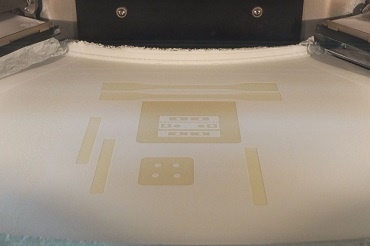

Fused Deposition Modelling (FDM) – A material extrusion printing process where a thermoplastic filament is melted and applied in layers through a nozzle. This is also referred to as melt strand deposition or Fused Filament Fabrication (FFF).Selective Laser Sintering (SLS) – A powder bed fusion printing process where raw material in powder form is fused layer by layer with a laser.

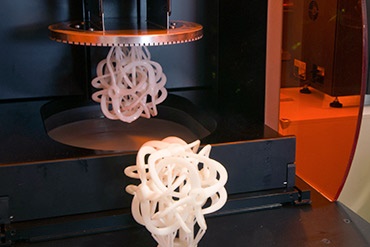

Stereolithography (SLA) – A vat photopolymerization printing process where a build platform is slowly lowered into a vat of photo-polymer resin and selectively cured by a UV laser.

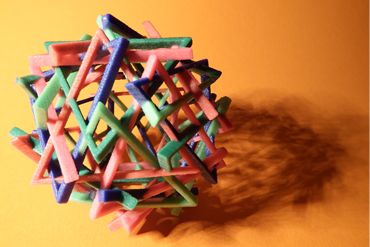

Multijet Modelling (MJM) – An inkjet printing process where several printheads move horizontally placing layers of photocurable plastic resin or casting wax material on top of each other. The material is cured with the help of UV light.

Selective Laser Melting (SLM) – A powder bed fusion printing process that’s similar to SLS. The main differences are SLM uses a metal powder to create parts, and a laser melts the material to form a homogenous part instead of sintering it.

Fused Deposition Modelling (FDM)

- Cost-effective

- Fast operation

- Minimal material waste

- Pressure direction defines the way the object can absorb forces

- Very thin wall thicknesses cannot be produced

- Support material is required

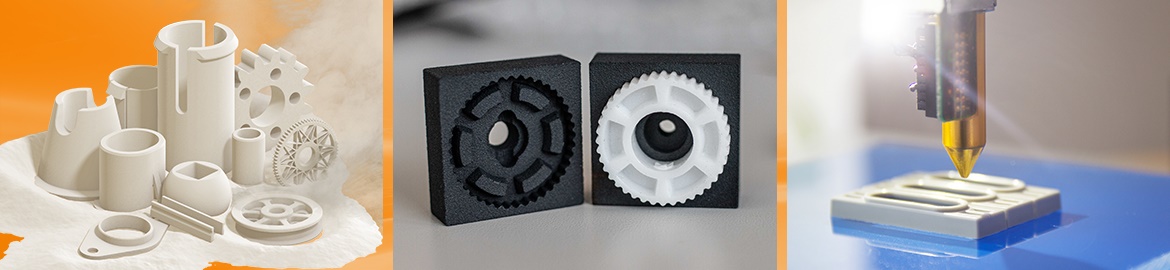

Selective Laser Sintering (SLS)

- Very delicate components can be produced

- Also suitable for larger quantities

- Thin wall thicknesses are possible

- No supporting structures needed

- Mechanically and thermally resilient

- High energy consumption

- Transparent structures are not feasible

Stereolithography (SLA)

- Currently considered the most accurate method

- Very smooth surfaces

- Flexible and locking objects are possible

- Multi-part assemblies are possible

- Component may be brittle under certain circumstances

- Design freedom can be limited due to the required support structure

Multijet Modelling (MJM)

- Various materials can be combined with each other

- High degree of detail with the finest structures

- Large installation spaces possible

- Smaller material selection

- Limited mechanical specifications – not suitable for functional prototypes

Selective Laser Melting (SLM)

- Almost pore-free material

- Moving parts can be made

- Design freedom

- Only about 50% of excess powder is reusable

- High energy consumption

- Surfaces often must be reworked

3D Printing Blog

Read the blog

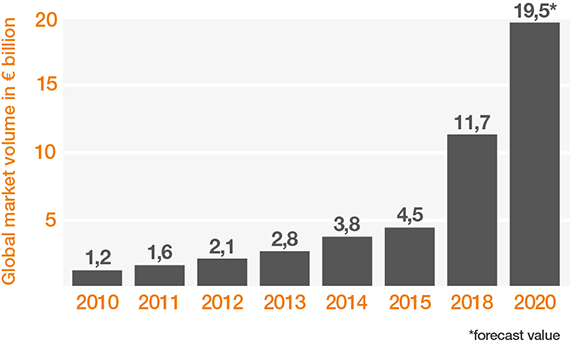

The development of 3D printing

3D printing was invented in the 1980s, with the most significant developments occurring in recent years. It’s also becoming more common for 3D printing to be used for industrial production. The global 3D printing market is expected to reach $22.4 billion by 2020.The 3D printers will continue to evolve rapidly:

- Installation spaces will expand so that larger or more parts can be produced at the same time

- Production speed will increase, and precision will continue to improve (e.g., SLS/SLM: variable laser focus, multiple lasers 400W and 1000W)

- Different materials for one object will be combined more efficiently (this is already possible for certain printing processes)

- The mechanical and optical properties of the final printed product will be optimized, reducing the reworking