Change Language :

Wear examination of igubal® pillow block bearing

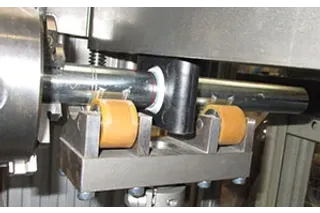

Carrying out the experiment on universal test bench

Customer's test on galvanized and stainless steel shafts

A customer is constructing a solar energy system, where its moving solar panels follow the sun. To identify a suitable pillow block bearing for the pivoting movement of bearing points, the application was reproduced on the universal test bench in the igus® test laboratory.

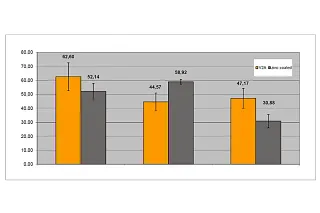

The goal of the test series was to determine for the customer the most wear-resistant pairing of shaft and iglide® material.

The test was carried out under the following test parameters:

Shaft material: V2A steel and galvanized steel

Bearing: igubal® pillow block bearing with spherical balls made of iglide® L280, J, and J4

Load: 725 psi

Pivoting angle: +/- 75°

Cycles: 30,000

Speed: 10 cycles/min

Conclusion:

With a wear rate of 30.88 µm/km the pairing of iglide® J4 with a shaft made of galvanized steel is the solution with the least wear. It should be mentioned that there was hardly any wear on the galvanized surface of the shaft. The spherical balls made of iglide® J4 is very gentle on the shaft, whereby the rust protection is maintained for a long time.

Do you wish to test a custom application?

We will gladly test your specific application as well. Simply use the contact form on the back!