Change Language :

DryLin® HTS - Product range

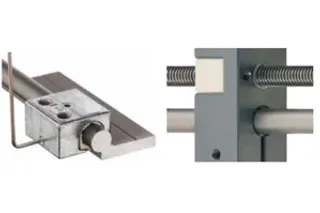

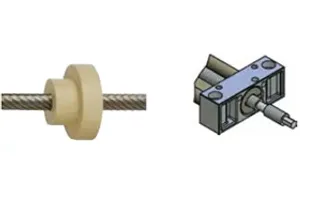

Adjustable radial clearance

The "turn-to-fit" feature allows individual clearance adjustment by hand. The advancement is done in 0.01 mm increments, and cannot accidentally loosen during operation (SLW type series 10-20).

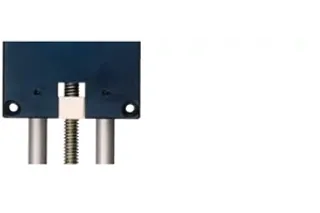

Camber

The optional axial pretension reduces the backlash of the system. Positioning accuracy and repeatability can be optimized. The required drive torque is increased only slightly.

Right-left and reverse

Besides the standard right-handed spindles, left-handed or counter-running spindles can also be used. This option, which is widely used in format changes, can be implemented for all diameters and type series.

Shaft materials

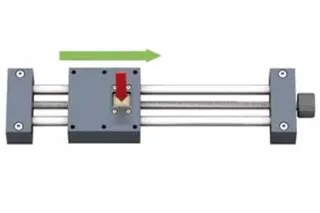

When using linear axes of the HTS type series, one can select from the shaft materials - steel, stainless steel, or hard anodized aluminum (standard). The short delivery time and excellent coefficients of friction and wear make the aluminum version the most widely used standard.

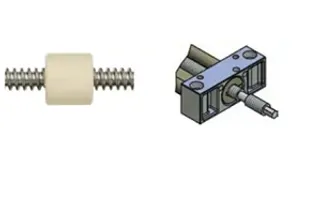

Trapezoidal thread spindle materials

Steel and stainless steel versions are available for the trapezoidal threaded spindles. Solutions with hard-coated aluminum spindles are also available on request. Steep threaded spindles and metric threaded rods are always made of stainless steel. The spindle ends are tapered up to the spindle diameter of 14 mm. On request, pins or special machining can be added.

Steep thread spindle materials

All steep threaded spindles are made of stainless steel. Compared to trapezoidal thread, the steep thread displays significantly higher pitches. So, higher travel speeds are possible, but at a higher drive torque compared to the trapezoidal thread. Available diameter and pitch: 8 x 15, 10 x 12, 10 x 50, 18 x 100.

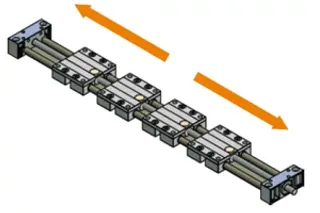

Fast Forward

HTS linear tables and HTSP plastic linear tables with quick release mechanism offer a combination of accurate positioning and quick manual adjustment.