Change Language :

Experience the future with i.CEE: predictive maintenance

Eliminate unplanned downtimes and increase machine availability

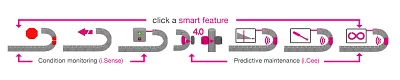

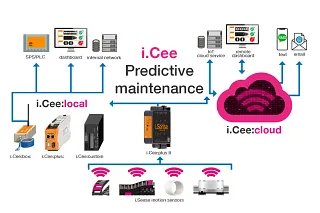

The smart networking of individual components creates the solid foundation for predictive maintenance concepts. At igus®, predictive maintenance is referred to as "i.Cee". The central element of this system is the i.Cee software. Sensors on e-chains®, plain bearing bushes, or a linear carriage transform igus® solutions into smart products. This upgrade can determine your igus® product's maximum service life and recommend when to perform maintenance. Algorithms adapt the service life and the service time to the equipment's use.

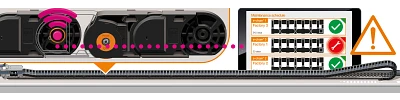

The i.Cee hardware

You determine the access of data transfers

i.Cee:local

Your data never leaves your corporate network, since the i.Cee software communicates only within the networks you want it to. The options range from an e-chain® within a single machine to a machine park and your own output interface.

i.Cee:cloud

This online solution has two options. In the first, your data is transferred directly to the cloud, where it is made available in a protected area that can be accessed with a browser dashboard. In the second, the data go to an intermediate location on the i. Cee.net: a so-called data concentrator allowing you to stop or adjust data exchange in the cloud.

i.Cee LIVE Dashboard Demo!

The i.Cee Dashboard visualizes all information and movement data of our smart trade show machine online and in real-time at the igus® virtual-real trade show stand in Cologne.

Smart plastics industry 4.0 solutions, tools and applications

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert