Change Language :

Energy Chain Cable Carriers: The Right Material for Any Cable Chain Application

Cable carriers are often an afterthought for many design engineers, but many times, they are the key to protecting vital cables and hoses on automated machinery. Cable carriers can be considered the lifeline that keeps a machine running. They not only guide the cables and hoses, but protect against harsh external elements, including dirt and dust, flying debris, chemicals and excessive heat.

energy chain high-performance plastic cable carriers from igus deliver easy installation, low-wear under adverse environmental conditions and a long service life even in extremely dynamic motions. In addition, energy chain cable carriers have a modular design and can be used in many different types of applications. No matter how intricate or simple the project, there is an energy chain cable carrier that provides a low maintenance, cost-effective solution.

energy chain cable carriers are available in a wide range of sizes, styles and high-performance plastic materials. All of igus®' standard materials are extremely versatile and ideal for almost any application. For those applications with excessively harsh elements, igus has developed special materials able to withstand a laundry list of extreme elements.

The following “Material Guide” outlines the different options available.

High Standards for Every Cable Chain Material

igus® offers more than 70,000 different energy chain systems in a number of different high-performance plastics. No matter what the material, every energy chain has the same basic properties: a high level of elasticity, high-abrasion resistance and the ability with withstand changing pressures and tensile loads. energy chains can also be used in a wide range of temperatures indoors and outdoors and are UV-resistant. Their plastic construction ensures they will never corrode when exposed to humidity, salt water and other environmental influences.

igumid G: Universal Standard Material

igus®’ standard material for its energy chain cable carriers is igumid G, a high-performance plastic that possesses a variety of traits for a number of different environments. igumid G can handle strenuous loads and extreme temperatures. It is also abrasion-resistant and suitable for outdoor use. energy chains made from igumid G have been used in numerous applications from refrigerator blocks and steel mills, to farming equipment, medical devices and general manufacturing equipment.

- igumid G can withstand the following elements and environments:

- Dirt, dust

- Radiation

- Hot chips

- Chemicals

- Extreme temperatures from

- 40 degrees Fahrenheit to +212 degrees Fahrenheit

- Clean rooms

- Explosion areas

igumid NB: Flame-retardant Material

Similar characteristics of igumid G are found in igumid NB, the standard material for all EZ Chains®, a cable carrier featuring easy access to cables and hoses via a split crossbar along the outer radius. This particular energy chain must be very easy to open and therefore, igumid NB combines flexibility and strength to enable easy cable routing and crossbars that can be opened or closed simply by hand. These chains have the following flame-retardant classifications:

- UL 94 classification - V2

- VDE 0304 Parts 3-5.70 classification - llb

- DIN 4102 flammability of materials - B2

igumid HT: Chip-repellant Material

energy chains made of igumid HT, a special material for high temperatures, is ideal for machine tool and steelwork applications. The fully enclosed design prevents hot flying debris, such as metal chips, from damaging cables and hoses. The material can withstand debris up to 1,500 degrees Fahrenheit and higher, which was previously only possible with steel chains.

igus®’ RX Energy Tube is made of igumid HT. In addition to being able to repel hot chips, its smooth, domed outer contour ensures it is nearly 100 percent chip-proof. All debris, such as metal chips, simply falls off. A series of comprehensive tests—including underwater experiments and tests measuring chip-mass penetration—have been carried out in igus®’ test laboratories to confirm the energy tube is nearly 100 percent airtight. Despite its rugged design, the RX Energy Tube can be easily opened using a screwdriver to unscrew bolts integrated into the outer radius of each link.

igumid DT: Magnetically Detectable Material

For applications in the food production and tobacco industries, there is igumid DT. The base compound of igumid DT was modified so that even the smallest fragments (as small as 1 millimeter) are detected by all standard metal detection systems. This ensures that in the event of a system or machine malfunction, chips can be detected and can be safely removed from the product.

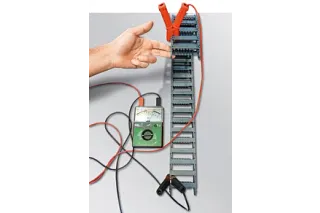

ESD: Electrostatic Discharging Material

Special ESD (electrostatic discharge) cable carriers are used in numerous industrial sectors. When designing a cable carrier system into an ESD application, there are two important reasons to use special cable carrier systems: first to prevent ESD from seriously damaging sensitive electronic components during the manufacturing process; and also, to curb safety concerns in applications that involve using, processing or storing hazardous or flammable materials.

The material of the cable carrier is critical to ensure it is suitable for ESD environments. igus® developed the material igumid ESD, which immediately dissipates electrostatic charges in controlled manner. igumid ESD has been tested to millions of cycles in a wide number of different applications. These cable carriers possess higher rigidity and have approximately 15 percent lower density, which makes them ideal for longer, unsupported travel lengths. The ESD energy chains are also durable, maintenance-free and can withstand harsh environmental conditions.

igumid GE: Clean Room Material

Clean room environments put especially high demands on the wear resistance of any automated systems. igumid GE is specially designed for clean room applications and igus®’ Series E6 and E14 cable carrier ranges are made of this material. It has been tested by the Fraunhofer Institute for Production Technology and Automation (IPA) in the area of clean room compatibility and micro-production.

Unsupported Length Material: igumid XXL

igumid XXL is a new material designed to cantilever up to 22 feet in length without guide troughs and supports. With this new material, installation efforts and costs are reduced, especially in gliding applications that require costly cable carriers, additional guide troughs and more space. igumid XXL is ideal for handling and conveying equipment, construction machinery and large robots.

The Benefits of So Many Materials

energy chain cable carriers are available in a wide range of materials for the most simple to the most demanding applications. igus®' standard material, igumid G, is an ideal choice for most applications and can be used in various environmental conditions. However, for applications with special requirements, having a breadth of high-performance, specialty materials makes it easy for any design engineer to find the perfect solution – while saving time and money by avoiding the need for expensive, custom solutions.

Discuss your project with an expert

Whether you're interested in end-to-end, fully assembled solutions or looking to build your own customizable project, let us assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 521-2747 to discuss your project today!