Change Language :

iglide® Q Testing

Able to withstand high loads, even when subjected to the strain of tumbling

The customer uses lubricated brass bearings that run on customer's steel shafts (Figure 1). Application data were also provided. (Table 1).

The igus® laboratory carried out tests in order to compare the wear of different iglide® materials with competitors' bearings and find the ideal material for this application.

Figure 1: Brass bearings and customer's shaft

Table 1: Application parameters

| Parameters | Value |

|---|---|

| Bearing material | Brass bearings (competitors); iglide® Z; iglide® Q |

| Shaft material | Steel |

| Movement | Displacement: tumbling (with bulldozer effect) |

| Speed | 0.49 f/s (corresponds to 74 rpm in the test) |

| Cycle | 4 rotations (10 s), 90 s pause |

| Load | 435 psi to 4,134 psi (increases every time a rotation is completed) |

There was no standard test set-up for the application parameters indicated. For this test, a new test set-up (Figure 2) was planned, designed and built - For the test, a constant load instead of an increasing load was used in order to expedite the test and keep it relatively simple.

In order to be able to rule out temperature influences due to continuous movement - something that differs from the real conditions of use -, a test interval of 6 s movement and a 54 sparse was set.

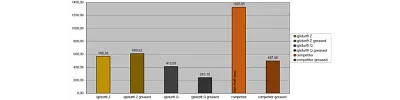

Wear when subjected to the stresses of tumbling (bearing moves around the shaft = Bulldozer effect) :

iglide® Z bearings, iglide® Q bearings and competitors' bearings made of brass were tested dry as well as with lubrication on the customer's steel shaft; p = 14.67 MPa (2,128 psi ); n = 74 RPM

Y = Wear rate [µm/km]

Figure 3 : Test results

The wear of iglide® Q when dry and also when lubricated is the lowest in this test. In addition, the tested parts were subjected to a visual inspection. The results are shown in Figure 4, Figure 5 and Figure 6.

Figure 4: Brass bearing with associated shaft after being in operation (examples)

Marks on the bearings and shaft were visible.

Figure 5: iglide® Z bearing and associated shaft after being in operation (examples)

There are almost no visible signs of damage on the sliding surface.

The bearings have a few marks on the inner diameter surface caused during initial wearing-in of the bearings.

Figure 6: iglide® Q bearing and associated shaft after being in operation (examples)

Conclusion:

In this test, the iglide® Q material showed the least amount of wear and had the best results in the test bay.

The worst results were exhibited by the tested brass bearings due to the high level of bearing wear and the damage to the shaft.

dry-tech® test laboratory

In the dry-tech® test lab, over 135 trillion test movements are carried out each year

Tribopolymers developed for dry operation.

igus® develops polymer materials for new applications in the area of bearing tribology. Base polymers, solid lubricants and reinforcing materials are combined to achieve the perfect bearing properties.

These are confirmed in laboratory tests based on real conditions in practice in order to improve the materials used.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert