Change Language :

iglide® Plastic Bushings - Wear Resistance

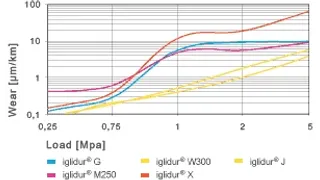

Figure 1.13: Wear of iglide® plastic bushings at low loads, shaft: Cf53, v = 3.937 ft/s

Wear resistance

Wear is an important measure when it comes to all kinds of machine components. For given loads and surface speeds, an iglide® plastic bushing's wear resistance alone can vary by a factor of 10 depending on the material pairing.

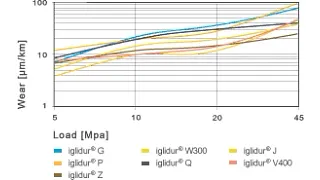

Wear and load

Different loads can greatly influence the wear rate of iglide® plastic bushings. With hardened, smoothed shafts, iglide® J is the most wear-resistant bearing material for low loads. iglide® Q, on the other hand, is more suitable for extreme loads.

Figure 1.14: Wear of iglide® plastic bushings at medium and high loads, shaft: Cf53, v = 3.937 ft/s

Wear and temperature

The wear resistance of iglide® plastic bushings varies little over a wide temperature range. However, in the maximum temperature range, the wear rate increases exponentially.

Table 1.8 compares the 'wear limits'.

One notable exception is iglide® T500. The wear resistance of these bushings actually increases with higher temperatures and reaches its optimum wear resistance at 320° F. Wear resistance then decreases again, gradually.

Picture 1.14: Test stand for extremely high loads up to 21,750 psi and temperatures up to 482° F, pivoting

Wear during abrasive dirt accumulation

Wear issues can occur if abrasive dirt particles get into bearings. iglide® plastic bushings offer a clear advantage in this area. Not only do they offer high wear resistance and oil-free operation, but also an extremely long service life. No oil or grease on the bearing means dirt particles can not penetrate as easily. If a hard particle does penetrate, an iglide® plastic bushing can absorb this particle. The foreign body becomes embedded into the bearing wall. Up to a certain point, operation can be maintained at optimal levels even when there is extreme dirt accumulation.

It is not only hard particles that damage bearings and shafts, but also soft dirt particles - for instance, textile or paper fibers - that are frequently the cause for increased wear. In these instances, the dry-running capability and dust resistance of iglide® plastic bushings are put to good use. In the past, they have been able to save costs in numerous applications.

Wear and surfaces

Shaft surfaces are important for the wear of bearing systems. In the same way that a shaft that is too rough can contribute towards bushing wear, a shaft can also be too smooth. A shaft that is too rough acts like a file and, during movement, separates small particles from the bushing surface. For shafts that are too smooth, however, higher wear can also occur. An extreme increase in friction results due to adhesion. The forces that act on the sliding partner's surfaces can be so great that regular material blow-outs occur.

The important thing to remember here is that wear from erosion is non-linear. Instead, it is subject to chance and can not be accurately predicted in advance.

Table 1.8: Wear limits of iglide® plastic bushings

| Material | Wear limit [° F] |

|---|---|

| iglide® G (formerly G300) | 73.4 |

| iglide® J | 158 |

| iglide® M250 | 176 |

| iglide® W300 (L280) | 248 |

| iglide® X (T500) | 410 |

| iglide® A180 | 158 |

| iglide® A200 | 80 |

| iglide® A290 | 176 |

| iglide® A500 | 374 |

| iglide® F | 266 |

| iglide® H | 248 |

| iglide® H4 | 248 |

| iglide® H370 | 302 |

| iglide® L250 | 248 |

| iglide® P | 100 |

| iglide® Q | 80 |

| iglide® R | 70 |

| iglide® UW | 70 |

| iglide® V400 | 266 |

| iglide® Z | 200 |

| iglide® B | 70 |

| iglide® C | 70 |

| iglide® D | 70 |

| iglide® GLW | 212 |

| iglide® H2 | 248 |

| iglide® J200 | 158 |

| iglide® T220 | 194 |

| iglide® UW500 | 374 |

Additional Technical Information

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert