Change Language :

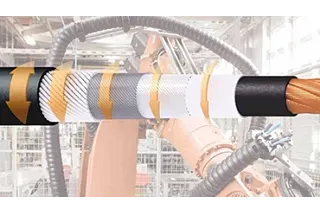

New robot motor cable for rotation angles of 180°/m in torsion applications

Targeted expansion of the product portfolio of robot motor cables with PUR outer jacket

Tested chainflex quality - also for robot cables

The special feature: Although the demands on the cable are very high, there is still the same guarantee as on all chainflex cables - 36 months. Why is that special? Highly torsional cables are also produced by other manufacturers. But nobody gives an exact statement about how long the cable will last in use and gives a guarantee on that. With chainflex, the service life calculator tells you exactly how long the cable will last and when it needs to be replaced. This is made possible by the igus "Torsion Test Standard", which is based on meaningful and comparable test results. According to this standard, all chainflex CFROBOT cables are twisted at least 5 million times in a triflex R energy supply system with a defined distance of one metre and a torsion of ±180°; naturally, the new CFROBOT7 cable also had to prove itself here.

All robot cables from chainflex

In addition to motor cables, igus also offers 6 other cable types especially for robots

How do rotary movements affect the cable?

Why do you actually need special cables for robot applications?

The increasingly complex movements in industrial applications demand torsional and/or three-dimensionally moving cables with a long service life, similar to the linear travels. Stranded conductors, core structure, shields and jacket materials have to compensate for circumference changes due to torsional movements, as well as significant flexural stresses. For this purpose various "soft" construction elements are used in chainflex CFROBOT cables, e.g. rayon threads (torsion force-absorbing filling elements) and PTFE elements for improved sliding performance. Special demands are made on the braided shielding in torsion cables. Torsion-optimized shield structures are chosen that can carry out the necessary compensatory movements thanks to special PTFE liners. The notch-resistant, halogen-free and flame-retardant PUR jacket compound for the motor cables protects the internal structure from possible damage. In contrast to linear movements, the "mechanical stress" for cables in robotic applications consists of a combination of bending and torsional forces, which usually cannot be determined in advance by design or measurement in the later application.