Change Language :

All-in-one: New customer portal for all smart plastics activities

Central i.Cee:portal allows secure control and configuration of all smart plastics components in a single location – at any time, from anywhere, on any device

Tech up

- Optimum transparency across all smart plastics components thanks to a central customer portal with all available machine data

- Quick, easy configuration of new smart plastics products with the central customer portal

- Secure (VPN) data connection for real-time access to machine parameters

Cost down

- No wasted time due to different platforms or configuration processes

- Central management of all available smart plastics assets in a single portal

Proof

- 50% faster asset setup than with a conventional, analogue approach

- Secure VPN connection

Sustainability

- Predictable service intervals save resource-intensive emergency operations

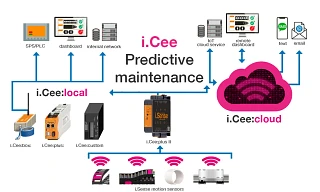

Smart machine data acquisition forms the basis for predictive maintenance concepts

Since the i.Sense Wonderbox is part of the smart plastics i.Sense condition monitoring system, all of its data can also be evaluated in the i.Cee control cabinet module. These data can then be used to digitally control the system's alarm and escalation management.

The i.Cee module can be integrated into predictive maintenance concepts in a number of ways, from preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which immediately reports any unforeseen change via various mobile channels. All information is collated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.