Change Language :

Clean, durable, and maintenance-free

Polymer plain bearings for sausage link cutting machines

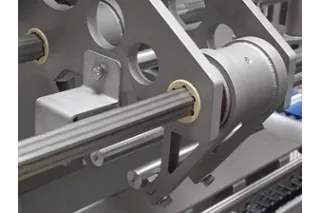

Linear guide in the area of the spreader mechanism.

In addition to convenient cleaning, the top priority for food production machinery is ruggedness. Highly aggressive cleaning agents and large amounts of water are used to prevent pathogens from developing. These must not have a long-term impact on machine availability. Self-lubricating polymer plain bearings that reliably stand up to any adversity over the long-term are proving themselves in this aggressive environment.

The hex guide was developed as a custom component, especially for the sausage link cutting machine.

"We are almost exclusively active in special purpose machinery building", explains Simone Singer from the sales and marketing operation of Singer & Sohn GmbH in Berching, Upper Palatinate. "And our proximity to the bratwurst metropolis Nuremberg has had the effect that our machines are frequently used in sausage and meat production. We see ourselves as problem solvers for our customers, who generally need to automate production processes with customized plants, in part to meet strict hygiene guidelines over the long term. “

Self-lubricating polymer plain bearings ensure malfunction-free operation. They are compatible with stainless steel as the friction partner.

Dieter Koller, Head of Design Engineering, explains: "Our machinery product range is characterized by its particularly high reliability, long service life, and ruggedness. This is particularly important in food processing applications, since these are frequently operated by unskilled workers on the one hand, while their service lives must be acceptable on the other. The market is highly competitive. Unnecessary maintenance and service downtime must be avoided at all costs. “

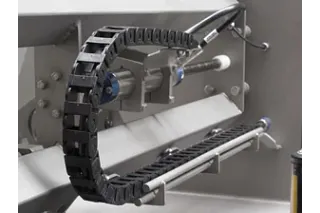

energy chains from igus® are also in use.

Hygienic cutting of sausage links

Founded in 1978 as a contract job-shop, today's focus of the family-run company with its roughly 38 highly qualified employees is on the design and fabrication of conveyor plants and special-purpose machinery that is primarily used in the food processing and beverage industry, but is occasionally also found in chemical and pharmaceutical applications. "No detail is too small for us. Ranging from a simple conveyor belt to highly complex machinery – we plan, fabricate, deliver and install cost-effective plants that have by now proven their performance capability throughout the world", explains Dieter Koller. "We are a one-stop shop, including service. " Ranging from conveyor lines for pastries and baked goods, scales, cutting plants, automatic production plants for processed meat or brush plants for salami sticks: they all involve customer specific products that are completely fabricated from stainless steel. "The material guarantees long-term and hygienic operation", explains Simone Singer. "Accordingly, all machinery elements must be compatible with this. “

Control panel cover with polymer plain bearing. In part, these prevent squeaking noises.

The custom machinery builder has now exhibited a sausage link cutting machine, 'OptiCUT SI-1000', at Anuga FoodTec, where the machine generated considerable interest. "This design was the result of a customer inquiry, who in part wanted to significantly reduce manual labor in his production for hygiene reasons. " Whereas in the past, employees manually cut the sausage links from below with a type of razor blade, this is now accomplished with a machine. Although employees were naturally required to wear protective suits, it was unavoidable that they touched the food while performing this work, therefore risking contamination. Moreover, the manual process continuously resulted in different sausage link lengths, which caused variability in the visual impression. "And in today's world, food retailers are no longer able to communicate this effectively to their customer base", the Head of Design Engineering raises another aspect.

Front: Simone Singer, Dieter Koller (both: Singer & Sohn GmbH), rear: Bernhard Hofstetter (igus® GmbH).

"The cutting operation is now accomplished fully automatically", explains Dieter Koller. A camera system optically recognizes the pinch locations and arranges the knife positioning, and therefore the accurate cutting of the sausage links. The output is currently at seven smoking trays (= triple edge aluminium rods) with 26 sausage pairs each per minute. "Our short-term objective is ten smoking trays", the Head of Design is quick to add. " The stainless steel plant can be used for a wide range of sausage types such as wieners, knockwurst in natural skins, fried or raw sausages. In connection with the material, it also meets all applicable requirements for cleaning and hygiene. "And because of the automatic cutting process, all sausages now have a uniform length for the packaging process."

Automatic stainless steel sausage link cutting machine.

Food production without external lubricants

The operating principle of the machine is straightforward. An operator removes the smoking trays with the sausage links from the boiler or smoking cart and feeds them into the sausage link cutting machine for automatic processing by the plant. The sausages are secured, spread, and respectively cut from below in the machines interior. The smoking trays exit from the opposite side of the plant and can then again be retrieved by an operator or are automatically fed to the next production process with add-on conveyor technology.

Focus on FDA compliance

In addition, cost-effective EFSM are installed with the machine as bearings for the pivot cylinder. Even the control panel hatch is equipped with a plastic plain bearing, which permanently ensures low-noise opening and closing. In addition, the machine also uses a hex edge guide made from iglide® J as a custom component. To address other end-user requirements especially in the food processing field, such as even higher resistance to temperatures or chemicals, or FDA compliance, liners made from a variety of J materials can be conveniently replaced with liners made from iglide® A180 at any time. This is a widely accepted FDA compliant material for applications with low to medium loads in direct contact with food and moisture.

"We consistently attempt to supply solutions from our extensive construction kit system", the competent technical sales consultant, Bernhard Hofstetter, explains in relation to the bearing technology topic. "However, if that fails to perform, we have the option of supplying samples or custom components starting at lot sizes of 1 as a means to supply our customers with the best solution. “

Continuous cleaning processes

The sausage link cutting machine is in use at the end-user at least five days per week for respectively three shifts. It is cleaned once a day This primarily affects the components with product contact. But spray water also comes into contact with the camera or the integrated operator terminal. "All interior and exterior areas must be able to permanently withstand water and cleaning chemicals", Dieter Koller highlights once again. "While the process is in operation, it is essential that malfunctions and/or unexpected downtime are avoided at all costs. “

The special purpose machinery builder relies on maintenance and lubricant-free polymer plain and spherical bearings as well as linear technology for its entire machinery and plant product range. They are cost-effective, easy to install, and are compatible with stainless steel. The collaboration between the two companies is very effective. "For instance, after we decided to use the new material, we were initially given 50 bearings to put through their paces. The results were so compelling, that we would never consider not using these today", Dieter Koller clarifies in conclusion. "And since we can predominantly rely on off-the-shelf components, we are also in good hands in terms of economic considerations. “