Change Language :

Test reports for data cables

Discover all our test reports on the durability tests for our data cables here.

Data cable CF240.PUR.02.18

Using the CF240.PUR in practice

Machine tools must deliver both durability and cost-efficiency. For engineers and operations managers, the service life of components directly impacts uptime and ROI. Modern control panels are slimmer, more powerful, and often movable — demanding flexible, high-performance cabling.

In harsh industrial environments, shielded data cables are essential. A robust, interference-resistant supply cable ensures reliable signal transmission and long-term performance. Choose cables engineered for machine tool applications to reduce downtime and extend equipment life.

Data cable CF298.05.04

Use of the CF298 in practice

In railway technology, reliability and safety are non-negotiable. Trains operate under strict safety standards and harsh environmental conditions, demanding robust components throughout. A critical example is the safety edge systems in train doors, where cables must perform under constant mechanical stress and within extremely tight installation spaces.

For engineers and rail operators, selecting a durable, space-saving cable designed for railway use is essential to ensure long-term functionality and compliance with industry regulations.

Data cable CF211

Use of the CF211 in practice

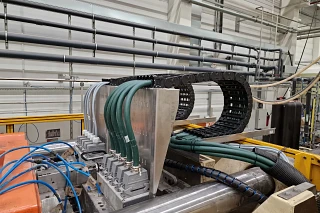

Injection molding is essential for mass production of precision parts like crown caps, toothbrushes, computer housings, and laundry baskets. These machines operate continuously at high speeds, placing intense electrical and mechanical demands on every component — especially the data cables.

The chainflex® CF211 data cable is engineered for these conditions. With a twisted pair design and overall shielding, it offers superior EMC protection and reliable, precise data transmission. Its durable PVC jacket performs exceptionally well in dry, high-temperature environments common in injection molding halls.

Ideal for short strokes and tight bending radii, the CF211 ensures a long service life, reducing unplanned downtime and boosting production efficiency. It’s the reliable choice for demanding motion applications in injection molding systems.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert