Change Language :

Test reports of motor cables

Discover all our durability test reports for our motor cables here.

Motor cable CF886.25.04 / CF896.25.04

Using the CF886 and 896 in practice

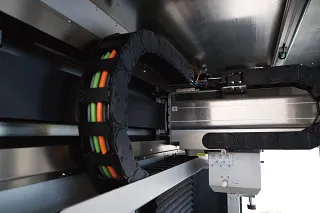

Machine tools demand both durability and economic efficiency. Selecting the right cable quality for each application is essential to optimize performance and reduce downtime. In laser cutting systems, where exposure to oil is minimal, flexibility and protection against dust and swarf are critical. The CF886 is the ideal choice, featuring an abrasion-resistant PVC outer jacket designed for dynamic applications in clean environments.

For machining centers where oils and coolants are present, cable resistance to chemical exposure is vital. The CF896 with its iguPUR outer jacket offers a cost-effective alternative to traditional PUR cables, combining oil resistance with durability—perfect for tight installation spaces and continuous motion.

Motor cable CF886.160.04

Using the CF886 in practice

In the woodworking industry—where sawing, routing, edging, and gluing are integral—numerous motors and drives must operate reliably, especially as automation continues to grow. Maintenance-free operation and process reliability are crucial in harsh factory environments.

The CF886 control cable is engineered for demanding conditions commonly found in woodworking plants. Its abrasion-resistant PVC outer jacket provides excellent protection against dust, wood shavings, and swarf, while its shielding ensures electromagnetic compatibility (EMC), preventing interference with nearby data and control cables.

Designed for global use, the CF886 offers long service life, flexibility, and UL approval—making it ideal for international machine builders and automated production lines in the wood industry.

Motor cable CF30.15.04

Using the CF30 in practice

Tight installation spaces, cleaning agents, dirt and many double strokes - all this can be found in a car wash. The CF30 is designed for such requirements and is also suitable for applications from +5 to +70°C thanks to the PVC outer jacket. The cable is oil-resistant and flame-retardant, has good sliding properties and can realise travels of up to 100m. It is important that this cable has UL certification for the international market.

Motor cable CF270.UL.25.04.D

Using the CF270.UL.D in practice

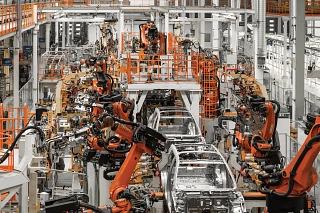

Process automation in the automotive industry saves time and money. Automation technology in the production line is a key aspect of this and requires a great deal of drive technology with motors and inverters. From the body shop to the paint shop to final assembly, the systems are located in different environments and come into contact with different materials. In all these areas, motor cables are needed that meet the strict requirements of the automotive industry.

Motor cable CF35.UL.25.04

Using the CF35.UL in practice

Waste recycling plants are not a clean place; high temperatures, dirt and usually long distances can be a problem for cables. Especially under the extreme conditions that prevail in waste management, however, it is important to have fail-safe systems. The CF35.UL is made for this. Whether extremely high humidity in a composting plant or the dust and dirt of thermal utilisation. Thanks to the TPE outer jacket, the cable is made for temperature ranges from -35 to +90°C and is not even affected by bio-oils. Long travels of up to 400 metres are just as little a problem as tight installation spaces or UV radiation in an outdoor system. As such solutions are of course used worldwide, the UL approval is also worth mentioning here.

Motor cable CF38.250.04

Using the CF38 in practice

Cable failures are certainly never desirable. However, a cable failure in crane and trolley travel is unthinkable. Reliability and maximum safety are required here. The motorised cables used are therefore exposed to major challenges. Temperatures from -40°C to +80°C are not uncommon. In addition, there are usually long travels and therefore high loads due to continuous use and dust. The motor cable used must be able to withstand all these conditions.

Motor cable CFROBOT7.25.04.C

Using the CFROBOT7 in practice

The aim of the test was to determine the service life of the twistable motor cable of the CFROBOT7 robot cable family. The CFROBOT7 is required to reliably withstand continuous movement, such as in a robot with a torsion of +/- 180°, as found in the automotive industry.

In these applications, it is often the case that the robots are constantly in motion and therefore the cables are constantly exposed to this torsion. Thanks to a folded overall shield and the robust PUR outer jacket, this cable is ideal for use in 3D movements.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert