Change Language :

e-spool® standard and HD options

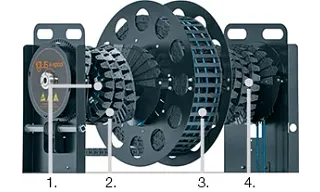

With the e-spool® standard and the HD version, cables in an energy chain are wound up in a space-saving manner. By using the twisterband, a wide variety of media can be guided without interruption. This means that adjustments and extensions of the filling system can also be made at any time.

Technical data

- Speed v - Max. 1 m/s

- Acceleration - Max. 2 m/s

- Transverse speed - Max. 1 m/s

- Lateral acceleration - Max. 1 m/s2 (radial) /0.25 m/s2 (axial)

- Versatile uses: energy can be supplied in all directions

- Low cost: twisterband enables rotary movement

- Variable energy supply system: guidance of all media in one system

- Space saving: e-chain® rolled up in the start position, keeping paths clear

e-spool® Standard - variant with one twisterband

R = extension right; L = extension left

| Part No. | Length [mm] | Weight [kg] |

|---|---|---|

| SP1.400.4000.01.L.0 | 4000 | 13.5 |

| SP1.400.4000.01.R.0 | 4000 | 13.5 |

| SP1.600.4000.03.R.0 | 4000 | 33 |

| SP1.700.7000.03.R.0 | 4000 | 38 |

| SP1.850.14000.03.R.0 | 4000 | 48 |

| SP1.600.4000.03.L.0 | 4000 | 33 |

| SP1.700.7000.03.L.0 | 4000 | 38 |

| SP1.850.14000.03.L.0 | 4000 | 48 |

e-spool® Standard - variant with two twister belts

R = extension right; L = extension left

| Part No. | Length [mm] | Weight [kg] |

|---|---|---|

| SP2.600.4000.03.R.0 | 4000 | 40 |

| SP2.700.7000.03.R.0 | 7,000 | 45 |

| SP2.850.14000.03.R.0 | 14000 | 55 |

| SP2.600.4000.03.L.0 | 4000 | 40 |

| SP2.700.7000.03.L.0 | 7,000 | 45 |

| SP2.850.14000.03.L.0 | 14000 | 55 |

e-spool® HD - variant with one twisterband

R = extension right; L = extension left

| Part No. | Length [mm] | Weight [kg] |

|---|---|---|

| SPHD1.400.4000.01.L.0 | 4000 | 17.2 |

| SPHD1.400.4000.01.R.0 | 4000 | 17.2 |

| SPHD1.600.4000.03.L.0 | 4000 | 52 |

| SPHD1.850.14000.03.L.0 | 14000 | 67 |

| SPHD1.600.4000.03.R.0 | 4000 | 52 |

| SPHD1.700.7000.03.R.0 | 7,000 | 56.5 |

| SPHD1.850.14000.03.R.0 | 14000 | 67 |

| SPHD1.1200.21000.01.0 | 21000 | 52 |

e-spool® HD - variant with two twister belts

R = extension right; L = extension left

| Part No. | Length [mm] | Weight [kg] |

|---|---|---|

| SPHD2.600.4000.03.L.0 | 4000 | 59 |

| SPHD2.700.7000.03.L.0 | 7,000 | 64 |

| SPHD2.850.14000.03.L.0 | 14000 | 74 |

| SPHD2.600.4000.03.R.0 | 4000 | 59 |

| SPHD2.700.7000.03.R.0 | 7,000 | 64 |

| SPHD2.850.14000.03.R.0 | 14000 | 74 |

Filling rules for standard e-spools®

Due to the special mechanical stress in an e-spool, we recommend using our chainflex® cables. In addition, we recommend adhering to the following filling rules:

1. In the linear chain, cables must only be placed next to each other - never lay several cables on top of each other!

2. In the case of unshielded cables, chainflex® cables with a TPE outer sheath should be used if possible.

3. Shielded cables should come from the chainflex® cable family, CFROBOT family.

4. The maximum bending radii of the twister belt used must be adhered to.

5. If possible, protect cables with dividers to prevent them from rolling over and abrasion against each other. To make the best possible use of the interior space, install the divider alternately in segments one behind the other.

6. Insert cables sorted by diameter or bending radius - insert thin, small, inwardly and outwardly increasing larger ones.

7. Relieve tension at both ends of the line. The cable tie knot must not be mounted in the direction of the chain.

8. The cables should be laid in the twisterband® in such a way that they have some distance/space reserve both outwards and inwards to the axis of rotation.

Installation instructions

In the case of a horizontal application, a smooth surface must be provided on which the energy chain can move.

Free Downloads

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert