Change Language :

1: Wear measurement test using oscillating movement for an iglide® plastic bushings from igus®.

Previous installments of TechTalk have discussed how using plastic bearings can help reduce wear and how different types of shaft materials affect wear and bearing life. In this installment, I’ll be discussing wear itself in more specific terms, and how different wear limits are dependent on certain application parameters and factors.

Considering the wear capabilities and limits of any machine component, particularly that of a plain bearing, is extremely important for applications across all industries. Design engineers have to consider many elements, including how day-to-day wear will affect machinery performance, how various application factors will cause different wear patterns, and how the wear limits of a bearing depend heavily on the type of application it is being used in, just to name a few.

Environmental factors

2: Wear tests using different types of shafting.

These are some of the environmental factors that can affect wear:

Shaft selection

Different shafting materials are recommended for different types of plain bearings. Each shaft-bearing combination will have different wear results. In some cases, wear on the shaft is more common than on the bearing itself. The best combinations for iglide® plastic bushings depend heavily on the bearing’s polymer material blend.

Loads

Different loads and pressures can influence wear. Some plain bearings are designed for low loads, some for high loads. For example, igus® offers a number of polymer material blends that have varying load capacities.

Speeds and operating motion

Speeds and operating motions, including oscillating, rotating and linear, have varying affects on plain bearings. Bronze bearings are ideal for rotational applications, while other plain bearing types might be suitable for several motions. The type of bearing you select will determine the amount of the wear that occurs.

Temperature

Temperatures can have little affect on the wear of a bearing or it can cause wear to increase exponentially. Plastic bushings, for example, are ideal for a wide range of temperatures, but once the maximum temperature is achieved, wear can significantly increase. Most bearings have a higher rate of wear as temperatures increase, but it also depends on the temperature-resistance of the bearing.

Dirty environments

Dirt and dust can become embedded between the shaft and the bearing, which causes wear. Self-lubricating plastic bushings offer an advantage in this situation: they operate oil-free so dirt and dust will not score the shaft or damage the bearing.

Exposure to certain types of chemicals

Certain chemicals can actually change the structural properties of a plain bearing, which decreases the bearing’s hardness and increases the wear.

Key Points

When Considering the Wear of Plain Bearings in an Application:

- Wear is measured by the amount of surface removed from the inner diameter (ID) of the bearing.

- Allowable wear limits are subjective and each application may have different requirements.

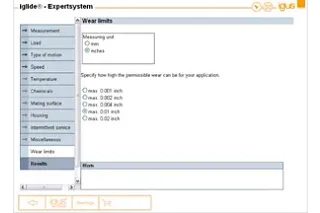

- It is beneficial to work with a manufacturer that offers lifetime calculations based on preset wear limits. For example, igus® specifies the wear limits (0.01 inch or 0.25 millimeters) of its plastic bushings within its lifetime calculator, the Expert System. The user has the option to choose what limit is acceptable from five different amounts of maximum wear.

3. igus® specifies the wear limits of its bearings within its lifetime calculator, the Expert System.

When Considering the Wear of a Plastic Bearing in an Application:

- The amount of clearance is often the most important factor when using plastic bushings. Depending on the amount of clearance and / or the application itself, this may affect the performance of the bearing.

Clearance is determined as follows:

Minimum ID after press fit – Maximum shaft diameter = Minimum clearance

Maximum ID after press fit – Minimum shaft diameter = Maximum clearance

For example, the acceptable starting clearance for igus®’ plastic bushings is between 0.002” (0.05mm) to 0.004” (0.10mm) to start. Therefore, the wear limits in igus®’ Expert System determine the measured amount of reduction on a bearing’s ID surface.

Keep in mind, you can change the preset wear limits based on your application requirements to achieve a longer life cycle, i.e. if you need tighter clearance, if your requirements are looser than what is suggested, etc.

*Always remember: Clearance = distance = free play between two parts (the shaft and the bearing) and does not depend on one part only!

- Once you reach the wear limit set by the Expert System, there will not be catastrophic failure. Keep in mind, there will be a wear surface riding on the shaft with a polymer bearing, however, it will remain fairly quiet even after wear occurs. In contrast, Teflon-backed bearings can be noisy as a result of metal-on-metal contact once the Teflon coating wears off.

Conclusion

Anticipating and calculating bearing wear is an important step when considering an application. There are numerous factors that can affect bearing wear and also influence the limits placed on a bearing’s life expectancy. If you have more questions on this topic or want to discuss your specific application, please call 1-800-521-2747 to speak with an igus® sales engineer or e-mail techupdates@igus.com.

Useful Links and Tools