Change Language :

Plastic Components for Pharmaceutical Packaging

Blister packaging machines and filling plants

In packaging plants of the pharmaceutical industry, polymer products from igus are used from the dosing station up to the labelling unit.

Regardless of whether this involves the blister packaging of tablets or the filling of pharmaceutical bottles: The bearing technology must always meet the highest hygienic standards and thus, for example, function reliably in maintenance-free dry operation without the use of lubricants.

igus Components and Application Examples

Below, exemplary stations of blister packaging machines and filling plants for pharmaceutical products and the igus products used are shown: Among others, iglide plain bearings, igubal pillow block bearings, drylin linear bearings, lead screw technology or tribotape® liners were installed here.

- 1. Dosing station

- 2. Weighing station

- 3. Circular filler / Rotary table (only for filling systems)

- 4. Film positioning (only for blister packs)

- 5. Cutting mechanism (only for blister packs)

- 6. Labelling station

Customer Application Stories

Transport technology rotary table

With the help of tribo-tape liner, plastic injection bottles are smoothly guided from a rotary table onto a conveyor belt.

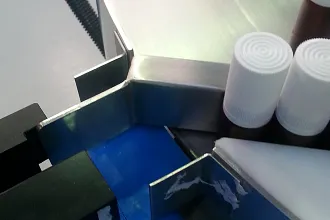

Cutting station for blister packs

Plastic products in the cutting mechanism for blister packaging are maintenance-free and have good torque resistance.

Labeling station

The drylin linear systems ensure the flexible adjustment of this labeler for the pharmaceutical, food and cosmetics industries.

Blister packaging machine / Cartoner

The igubal pillow block bearings, lead screw nuts and lead screws enable precise adjustment mechanisms in this cartoner for blister packaging.

Position adjustments for blister packs

Lightweight and hygienic drylin linear bearings perform position adjustments in this pharmaceutical packaging machine.

Contact Us

Questions or product information? Please contact:

igus® Canada Inc.+1 800 965 2496Contact an Expert

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert