Change Language :

Excavating and grabbing with an additional degree of freedom

Requirement: 4,000 hours maintenance-free operation under harsh conditions

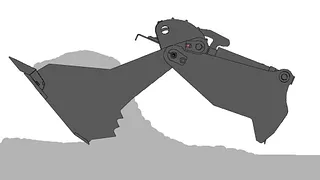

Where the iglidur bearings for an L&K grab bucket are fitted.

For around fifteen years, the base material of the L&K tools has been the extremely resilient Hardox steels from the Swedish steel producer SSAB. Similarly resistant components must also be used in the joints that tilt a high-tipping bucket, for example, or open and close the halves of a grab bucket.

The requirement profile for such bearing points is clearly defined. Dipl.-Ing. Roland Georgi, design engineer and responsible for quality management at L&K: "The bearings must achieve the same service life as the bucket. And they must be maintenance-free."

Lightweight design counts - even for excavator buckets

iglidur bushings are used as bearings in the joints of the grab buckets – maintenance-free, cost-effective and weight-saving.

Here, the designers, who work with modern CAD tools, originally used metal plain bearings with a sintered-on gliding layer. Five years ago, L&K trialed an alternative to this composite design for the first time and used bearing bushes made of iglide®. As a "mono-material", this high-performance polymer with incorporated lubricant manages without additional lubrication over the entire service life and is extremely resilient.

Mass plays an important role for the designers at L&K: "We manufacture moving components. If the blade is too heavy, the dynamics suffer. That's why lightweight construction is also an important trend for us, but the load-bearing capacity must not be compromised as a result."

Contact Us

Questions or product information? Please contact:

igus® Canada Inc.+1 800 965 2496Contact an Expert

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert