Change Language :

New dry cleanroom certificates

ISO Class 4 after 15 million double strokes in the dry cleanroom

Fraunhofer IPA certification: Long-term tests, high purity

[New] [certified]

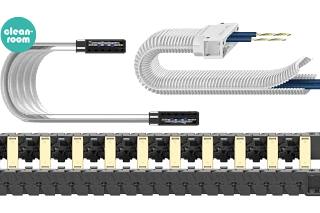

Two years ago, the E6.29 was the first certified energy chain for dry cleanrooms. Now, together with the Fraunhofer IPA, we have developed two new certificates that confirm the cleanroom suitability of the igus® energy chains in long-term tests: The two new certificates are divided into pre-aging and aging behavior.

Tech up

- Long service life of igus® energy chains: e-skin® flat system, E6, e-skin soft, easy chain E14 proven in the dry room

Cost down

- Constant or maximum gradation by one ISO class dry cleanroom over 10 months and 15 million double strokes

Proof

- New Fraunhofer IPA dry cleanroom certificates (standard, pre-aging and aging behavior)

Sustainability

- Sustainability: Longer service life of energy chains in dry environments conserves resources

Aging behavior at very low humidity

| Aging behavior in the dry cleanroom, test parameters | Result |

|---|---|

| Test 1, new, (after run-in phase 0 cycles) | 4 |

| Test 2, after 2 months (3.2 million cycles) | 4 |

| Test 3, after 4 months (5.1 million cycles) | 4 |

| Test 4, after 6 months (7.5 million cycles) | 4 |

| Test 5, after 8 months (10 million cycles) | 4 |

| Test 6, after 10 months (15.1 million cycles) | 4 |

| Overall result | Cleanroom class 4 |

You might also be interested in

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert