180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

| Gliding elements: | Maintenance-free |

| Material: | iglide® J * |

| Max. surface speed: | 15 m/s |

| Operating temperature: | -40°F to +194°F |

| *Other materials on request |

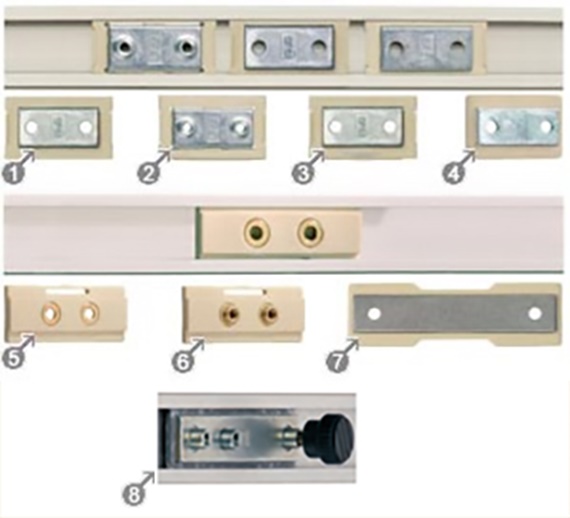

Rail made of anodized aluminum

2Gliding elements made of iglide® J or J200

3Carriage made of chromated zinc or plastic

4Carriage with threaded hole or through hole

Small installation height between 6 and 12 mm

Lightweight

Numerous carriage options – also with pretension

Maintenance-free, self lubricating

Corrosion-resistant

Low wear with low coefficient of friction

Rails in silver or black anodized

Variants: Standard, Preload (P), floating bearing (LL)

Extremely low weight

Quiet running

Installation height 6 mm

Up to 50 N load

Over 20 carriage options

9.5 mm installation height

100% self-lubricating

iglide® J plain bearing material

up to 500 N Last

Best selling linear guide

Lightweight

Installation height 9,5 mm

High speeds are possible (up to 5 m/s)

iglide® J plain bearing material

Up to 700 N Last

Installation height 12 mm

100% self-lubricating

Wide torque support

up to 1000 N Last

Gliding elements made of iglide® J or J200

Mounting rails: Anodized aluminum

Intermediate rail: Plastic

Options: Full extension, over extension (+ 20 mm), partial extension

Continuous lengths up to 1200 mm extended total length

Self-lubricating

Low noise

Corrosion resistant

From stock

Easy installation

Low-cost

Dismantling possible

High retention force

Components made from aluminium and plastic

Self-lubricating

Entry-level model

Carriage-mounted lead screw

Retrofitting possible at any time

Small and compact

Based on self-lubricating DryLin® N low profile guides size 27

100 % self-lubricating

Lead screw, ball bearing mounted for low-backlash and dynamic operation

Manual and motorized operation possible

SLN-27: linear axis with NEMA11 stepper motor, lead screw ball bearing mounted via motor mount or ball bearing mounted linear axis with NEMA11 stepper motor

Small (installation height from 22 mm), light and flat

Plastic plain bearings in the bearing points

M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7

Manual and motorized operation