180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

| Gliding elements: | Maintenance-free |

| Material: | iglide® J* |

| Max. surface speed: | 15 m/s |

| Operating temperature: | -40°F to +194°F |

| *Other materials on request |

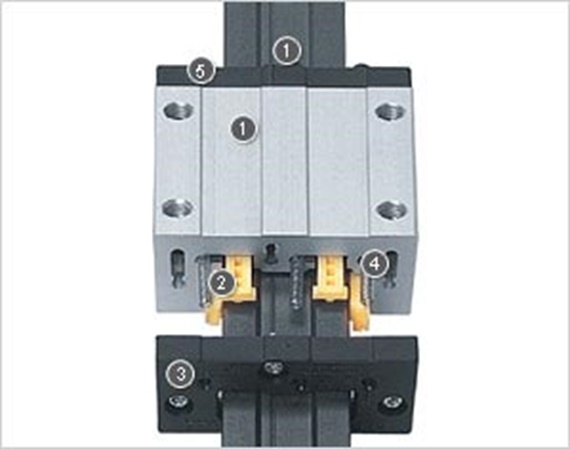

Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized.

2Six gliding elements made of iglide® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings.

3Alternatively, bearing clearance is continuously adjustable

4All steel parts are stainless steel

5The lid is made of solid plastic or stainless steel

100 % self-lubricating

Adjustable bearing clearance

Automatic clearance adjustment

High static load capacity

Service life up to 164,000,000 ft. without lubrication

High dirt resistance

Low vibration and low noise

When you want to save installation space

DryLin® N

DryLin® W

When you need a pure stainless steel solution

DryLin® W

DryLin® R

When you want to construct as economical as possible

DryLin® N

DryLin® W