iglide® A180 | The FDA-compliant all-rounder - Completely lubrication-free belt deflection

- The iglide® A180 material complies with food and drug administration (FDA) regulations for repeated contact with food

- Good media-resistance

- Low drive power

- Long service life of the belt

- Tight deflection radii

- For wet environments

- Good wear-resistance

- Long service life

- Lubrication-free and maintenance-free

- Standard range from stock

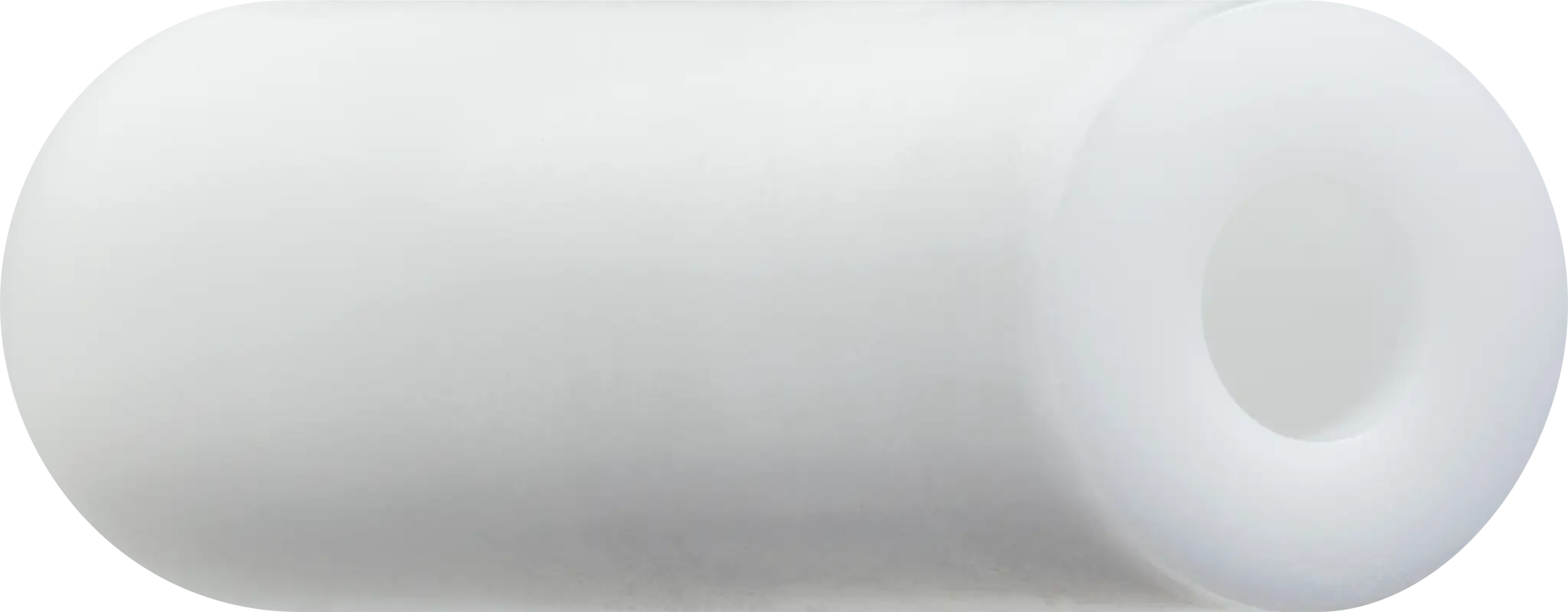

igus® has developed its own belt rollers to deflect conveyor belts in materials handling applications. The iglide® solution is characterized by tight radii and low required driving power. Bearings made from iglide® A180 are suitable for application in direct contact with foodstuffs. Hence they are the ideal solution for bearing locations on machines for the food and packaging industries, the medical equipment manufacturing, for small equipment for households, etc. The iglide® A180 distinguishes itself also in wet cleaning or where process-dependent contact with wet media is the business of the day by its extremely low humidity absorption.

Typical application areas Beverage industryFood industryMedical technology You can find further applications here:

Industry solutions When to use it?- When a maintenance-free belt roller is required

- When a precise guiding is required

- When a cost-effective and economical solution is required

- If the rollers have direct contact with food

- When FDA compliance is required

- If low quiet operation is required

- If low moisture absorption is requested

| When not to use it?- When high conveyor speeds

occur - When high forces are applied on the belts

- When a static belt roller is required

|