Change Language :

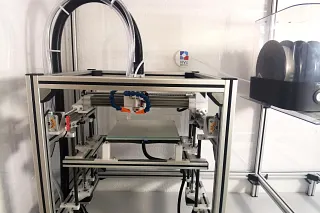

Processing of thermoplastics with the Vivecube cleanroom 3D printer

Using high efficiency high-helix and trapezoidal thread spindles for all drive axes proved to be the ideal solution for ensuring the cleanroom compatibility of the VIVECube. It was the only demonstrably suitable and cost-effective option for low-abrasion linear drives.

Application Overview

- What was needed: A precise, reliable cleanroom 3D printer for processing thermoplastics

- Requirements: Self-lubricating and maintenance-free, suitability for cleanrooms, no abrasion, cost-effectiveness

- Products used: Stepper motors with coupled dryspin® high helix leadscrews and flanged nuts with wrench flat made of iglide® A180, stepper motors with coupled trapezoidal leadscrews and flanged nuts made of iglide® A180, drylin® W single rails, drylin® R aluminum shafts, igubal® flange bearings, xiros® radial deep groove ball bearings

- Success for the customer: Using drylin® bearings with exchangeable sliding foils accelerated the VIVECube – Clean Precision design. The foils prevent particle release and ensure process stability, while suitable rail and shaft guides added further implementation benefits.

VIVECube – Clean Precision cleanroom 3D printer

Browse Applicable Parts

Contact Us

Questions or product information? Please contact:

igus® Canada Inc.+1 800 965 2496Contact an Expert

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert