180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

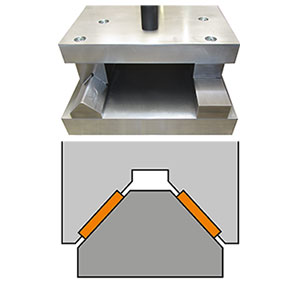

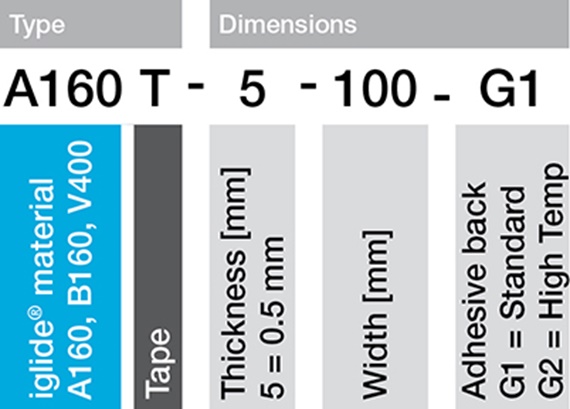

The tribo-tape liner from igus® can be used to line a variety of tribologically stressed surfaces and shapes to optimize transportation tasks, for machine beds, etc. With a thickness of 0.5 - 1 mm (+0.15 mm for tape with the adhesive back), the space requirement is very low. It is very easy to work with (the tape can be cut using scissors) and offers optional self-adhesive back on the liner which results in almost unlimited possibilities for use.

The iglide® tribo-tape liner is also available with a self-adhesive back for quick and easy installation. With a self-adhesive back, iglide® A160 / B160 / W160 can be used at temperatures up to 194 ºF and V400 up to 320 ºF.

Low coefficient of friction

Best wear-resistance

Up to 194°F

FDA-compliant

| Part Number | Tribo-Tape thickness | ||

|---|---|---|---|

| A160-T-005-0020 | 0.5 | 3.25 USD | |

| A160-T-005-0020-G | 0.71 | 5.22 USD | |

| A160-T-005-0050 | 0.5 | 6.94 USD | |

| A160-T-005-0050-G | 0.71 | 11.40 USD | |

| A160T-5-100 | 0.71 | 11.19 USD | |

| A160T-5-100-G | 0.71 | 16.87 USD | |

| A160T-0.5-500 | 0.5 | 20.31 USD | |

| A160T0.5-500G1 | 0.71 | 41.48 USD | |

| A160T-1.0-500 | 1 | 43.76 USD | |

| A160T1.0-500G2 | 1.21 | Upon request |

Extreme wear resistance

Low coefficients of friction

-40 °F to +194 °F

| Order number | Film width [mm] |

Film thickness [mm] |

|||

|---|---|---|---|---|---|

| B160T-5-20 | 20 | 0.5 | 3.25 USD | ||

| B160-T-005-0020-G | 20 | 0.71 | 5.22 USD | ||

| B160T-5-50 | 50 | 0.5 | 6.94 USD | ||

| B160-T-005-0050-G | 50 | 0.71 | 16.27 USD | ||

| B160-T-005-0100 | 100 | 0.5 | 11.19 USD | ||

| B160-T-005-0100-G | 100 | 0.71 | 16.87 USD | ||

| B160T-5-500 | 500 | 0.71 | 20.31 USD | ||

| B160T-5-500G | 500 | 0.71 | 41.48 USD | ||

| B160T-10.0-500 | 500 | 0.5 | Upon request | ||

| B160T-10.0-500G | 500 | 1.21 | Upon request |

Low coefficients of friction

Easy to cut

Optional self-adhesive back

Standard width from stock

Individual widths from 20 to 500 mm

| Order number | Film width [mm] |

Film thickness [mm] |

|||

|---|---|---|---|---|---|

| W160-T-005-0020 | 0.79 | 0.02 | 3.25 USD | ||

| W160-T-005-0020-G | 0.79 | 0.03 | 5.22 USD | ||

| W160-T-005-0050 | 1.97 | 0.02 | 6.94 USD | ||

| W160-T-005-0050-G | 1.97 | 0.03 | 11.40 USD | ||

| W160-T-005-0100 | 3.94 | 0.02 | 11.19 USD | ||

| W160-T-005-0100-G | 3.94 | 0.03 | 16.87 USD | ||

| W160-T-005-0500 | 19.69 | 0.02 | 20.31 USD | ||

| W160-T-010-0500 | 19.69 | 0.04 | 43.76 USD | ||

| W160-T-005-0500-G | 19.69 | 0.03 | 41.48 USD | ||

| W160-T-010-0500-G | 19.69 | 0.04 | 60.44 USD |

Extremely wear resistant

Highly resistant to media

-40°F (-58°F without adhesive back) up to 320°F

| Part Number | Tribo-Tape thickness | ||

|---|---|---|---|

| V400T-5-120 | 0.5 | 64.81 USD | |

| V400T-5-120G2 | 0.71 | 76.04 USD |

| General properties | Unit | iglide® A160 |

iglide® V400 |

iglide® B160 |

iglide® W160 |

Testing method |

|---|---|---|---|---|---|---|

| Density | g/cm³ | 1,0 | 1,51 | 1,0 | 0,95 | |

| Color | blue | white | black | white | ||

| Max. moisture absorption at 73 °F / 50% r.h. |

% weight | 0,1 | 0,1 | < 0,1 | < 0,1 | DIN 53495 |

| Max. water absorption | % weight | 0,1 | 0,2 | < 0,1 | < 0,1 | |

| Coefficient of sliding friction, dynamic against steel | µ | 0,09 - 0,19 | 0,15 - 0,20 | 0,13 - 0,20 | 0,12 - 0,20 | |

| pv value, max. (dry) | psi x fpm | 7,800 | 14,000 | 7,800 | 7,800 | |

Mechanical properties |

||||||

| Modulus of elasticity | psi | 166,938 | 652,700 | 123,600 | 115,900 | DIN 53457 |

| Tensile strength at 68 °F | psi | 2,756 | 13,780 | 2,031 | 2,031 | DIN 53452 |

| Compressive strength | psi | 5,366 | 6,817 | 5,366 | 5,366 | |

| Maximum recommended surface pressure (68°F) | psi | 2,176 | 6,527 | 1,595 | 1,450 | |

| Shore-D hardness | 60 | 74 | 59 | 58 | DIN 53505 | |

Physical and thermal properties |

||||||

| Max. long-term application temperature (with self-adhesive back) |

°F | +194 | +320 |

+194 | +194 | |

| Max. short-term application temperature (with self-adhesive back) |

°F | +212 | +356 (+338) |

+212 | +212 | |

| Lower application temperature (with self-adhesive back) |

°F | -58 (-4) | -58 (-4) | -58 (-4) | -58 (-4) | |

| Heat conductivity | [W/m x K] | 0,30 | 0,24 | 0,32 | 0,30 | ASTM C 177 |

| Coefficient of thermal expansion (at 73 °F) | [K-1 x 10-5] | 11 | 3 | 11 | 11 | DIN 53752 |

Electrical properties |

||||||

| Specific contact resistance | Ωcm | > 1012 | > 1012 | > 1012 | > 1012 | DIN IEC 93 |

| Surface resistance | Ω | > 1012 | > 1012 | > 1012 | > 1012 | DIN 53482 |

| Chemical resistance | iglide ® A160 | iglide ® V400 | iglide ® B160 | iglide ® W160 |

|---|---|---|---|---|

| Alcohol | + | + | + | + |

| Hydrocarbons | + | + | + | + |

| Greases, oils without additives | + | + | + | + |

| Fuels | + to 0 | + | + to 0 | + to 0 |

| Diluted acids | + | + | + | + |

| Strong acids | + | + | + | + |

| Diluted alkaline | + | + | + | + |

| Strong alkaline | + | - | + | + |

| Radiation Resistance [Gy] up to | 1 x 105 | 2 x 104 | 1 x 105 | 1 x 105 |

Monday to Friday from 8 am - 5 pm

24h