Change Language :

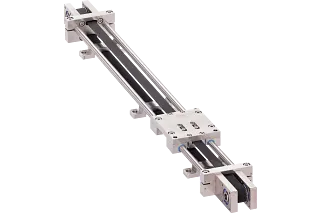

Ready-to-install toothed belt axis

The new ZLW-toothed belt axis ZLW-1050-ES made of stainless steel extends the product range of igus® toothed belt axes. It is characterised by its narrow type and corrosion resistance. With a centre distance of 50 mm, it is extremely compact and is ideal for use in small installation spaces, as a single axis or in parallel operation as well as gantry superstructures. Thanks to the use of stainless steel, the ZLW toothed belt axis is extremely corrosion-free, extremely robust and suitable for long maintenance-free operation. The linear slides of the ZLW-toothed belt axis are equipped with drylin® linear bearing foils made of iglidur® E7, which ensure high running performance and freedom from maintenance. The linear plain bearings are self-lubricating and therefore particularly easy to clean. The timing belt is a neoprene timing belt with glass fibre reinforcement and RPP 3M toothing. The belt tension can be conveniently adjusted centrally on the carriage. For high-frequency applications such as 24/7 use, suitable linear plain bearings are available for quick bearing changes in seconds. The linear bearing foils can be easily replaced without dismantling the system.

Tech up

- Extremely durable thanks to stainless steel components

- Corrosion-resistant

- A ZLW stainless steel linear module with a compact width (50mm) is being added to the drylin® modular system

Cost down

- Ready-to-install system

- Individual configuration (stroke length/drive)

Proof

- Tested in the igus® laboratory: drylin® W linear system, Ø 10mm, carriage length 100mm, iglidur E7 liners, load 30N, service life 4,000km in continuous operation until bearing replacement

Sustainability

- 100% lubrication-free through the use of igus® polymers in the bearing points

The ZLW-1050-ES toothed belt axis in detail

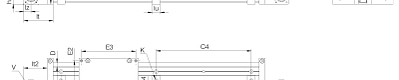

Technical drawing

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 5 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert